Features January to June 2021

Item 2101

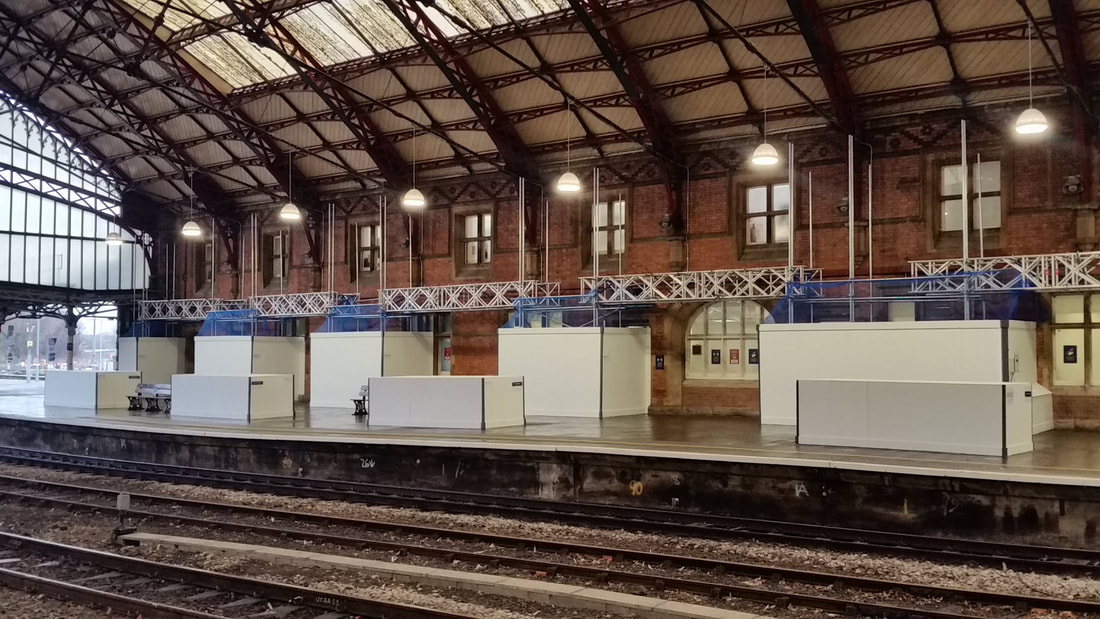

Bristol Temple Meads station refurbishment Work commenced January 2021;

Item 2102

Reopening the branch to Okehampton - A collection of pictures

Item 2103 Relaying the St Ives branch

Item 2104 Remember the Royal Mail trains. Paul Barlow

Item 2105 Trewoon gets a new bridge.

Item 2106 St Austell Goods Station through the up & down loop to St Austell Station

Item 2107 Accident on the Fowey branch. Guy Vincent

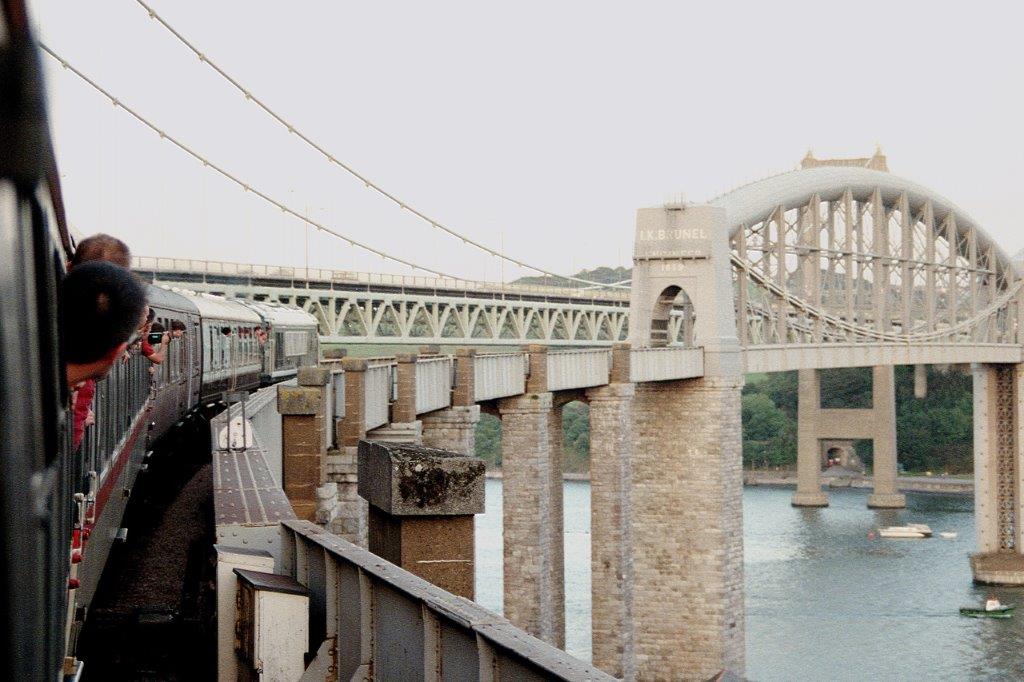

and additional Fowey branch passenger specials in 1994.

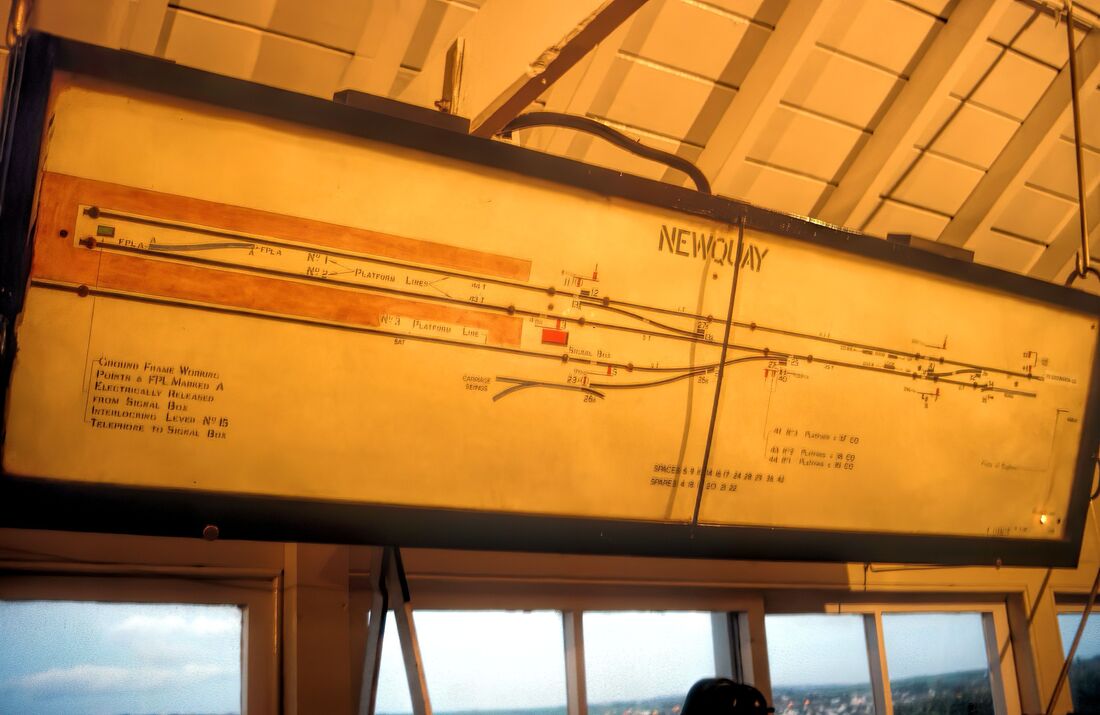

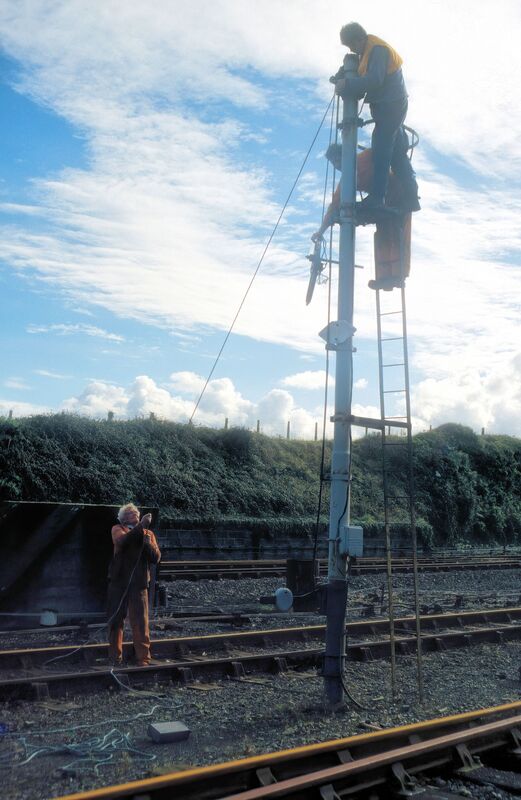

Item 2108 The closure of Newquay signalbox - a photographic record by Alan Peters and Gary Rainbow.

Item 2109 The 'Private Charter' to and from Penzance 4th, 5th, 6th & 7th April 2021.

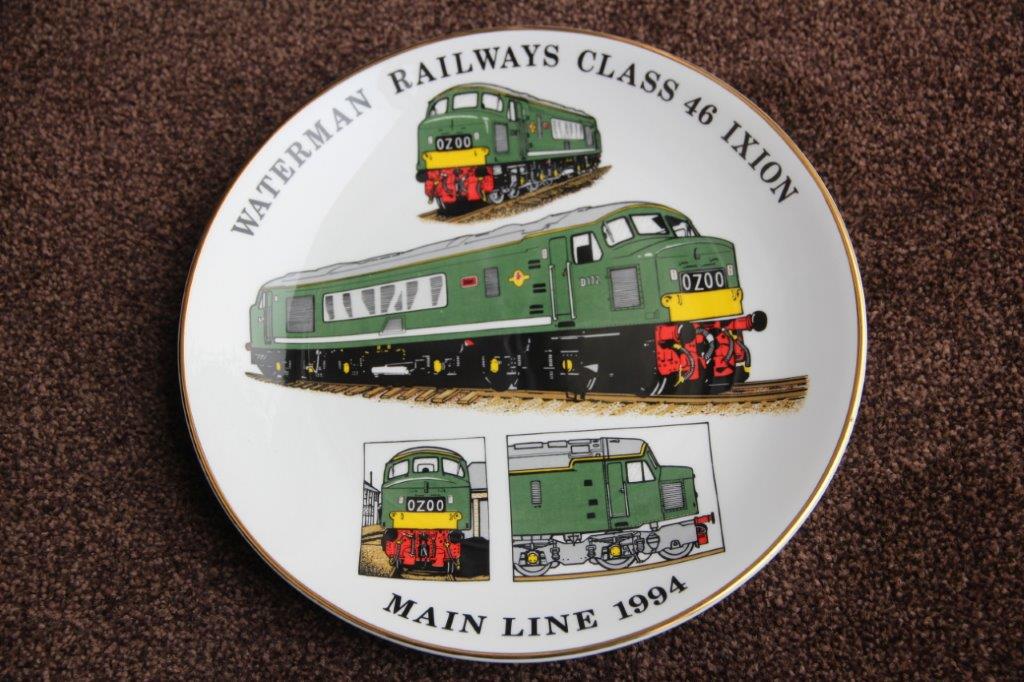

Item 2110 The story of 'Ixon' and a collection of D1015 Western Champion, Paul Barlow.

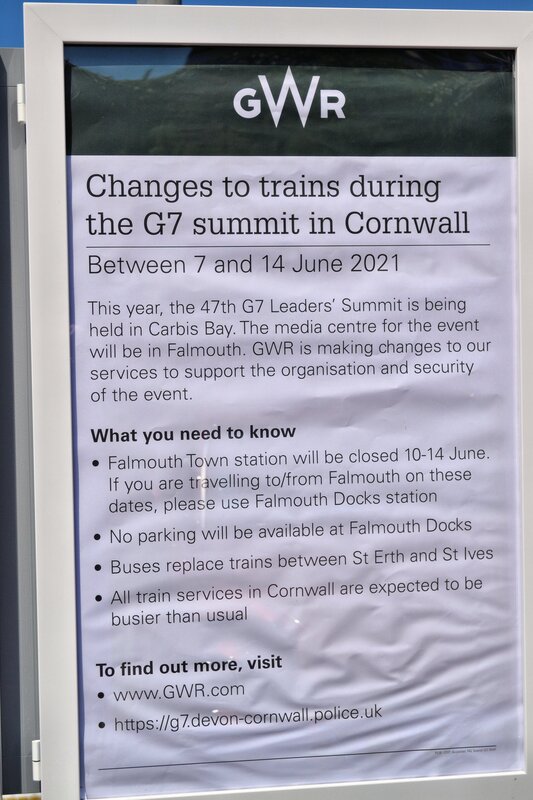

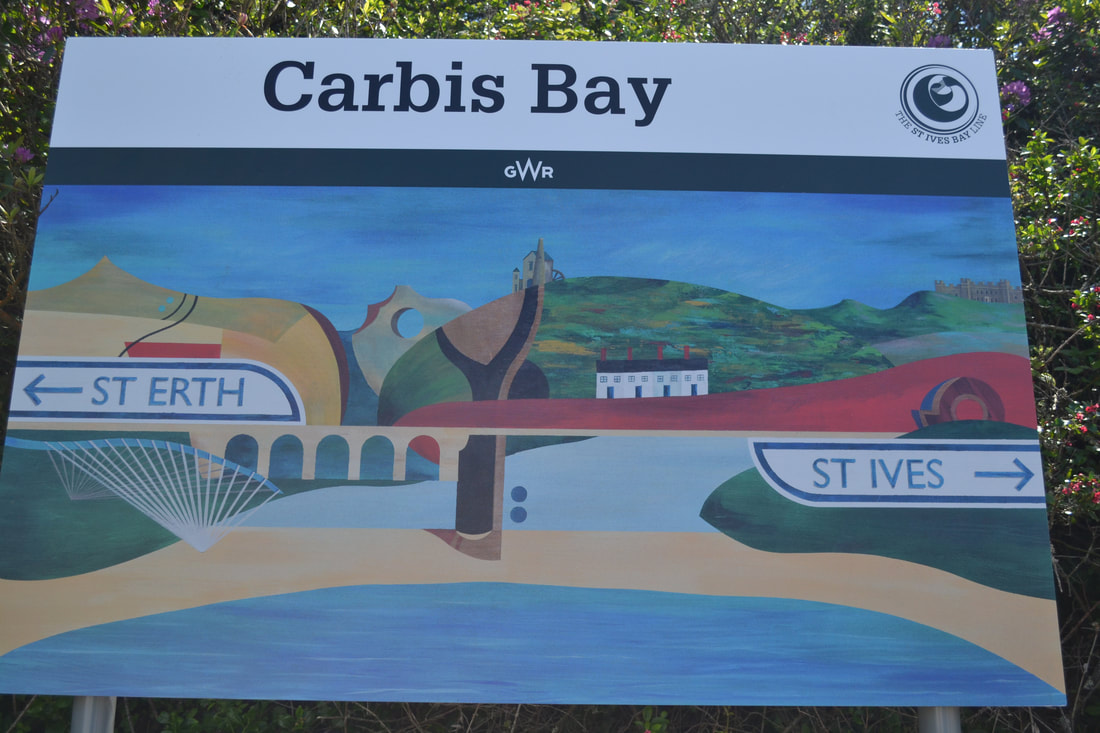

Item 2111 'G7 and all that'. A collection of pictures of railway happenings associated with the conference at Carbis Bay in early June.

Item 2112 Railtours into Cornwall Spring and early Summer 2021

Item 2113 THE GRANGE CLASS of the GWR An article by Michael L. Roach

Item 2114 Royal Train Formation 11th June 2021 An article by Guy Vincent.

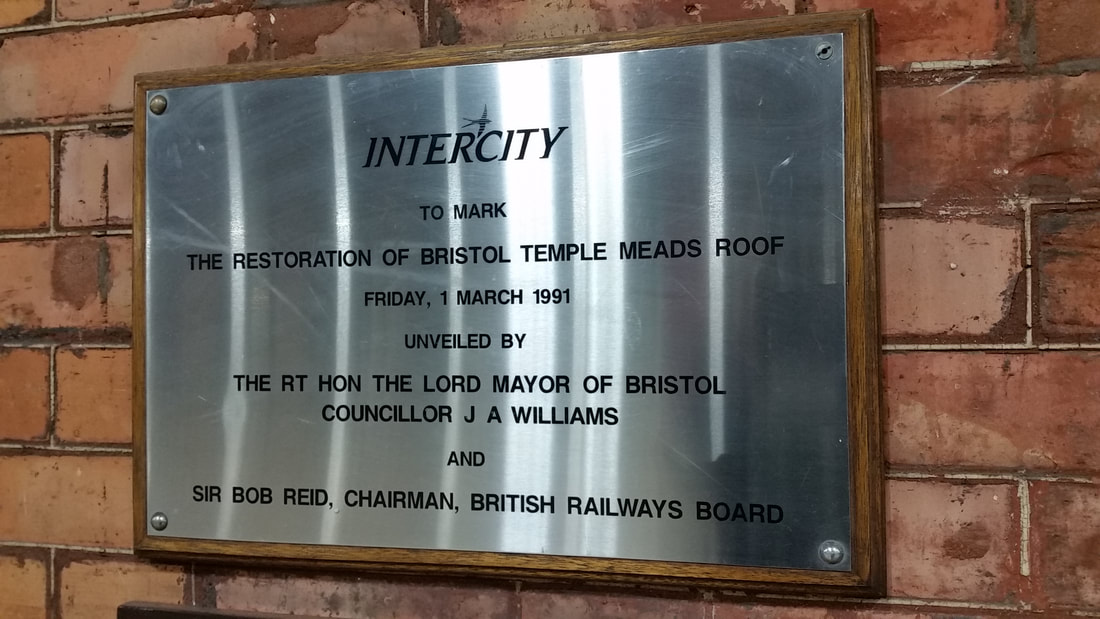

Bristol Temple Meads station refurbishment Work commenced January 2021;

Item 2102

Reopening the branch to Okehampton - A collection of pictures

Item 2103 Relaying the St Ives branch

Item 2104 Remember the Royal Mail trains. Paul Barlow

Item 2105 Trewoon gets a new bridge.

Item 2106 St Austell Goods Station through the up & down loop to St Austell Station

Item 2107 Accident on the Fowey branch. Guy Vincent

and additional Fowey branch passenger specials in 1994.

Item 2108 The closure of Newquay signalbox - a photographic record by Alan Peters and Gary Rainbow.

Item 2109 The 'Private Charter' to and from Penzance 4th, 5th, 6th & 7th April 2021.

Item 2110 The story of 'Ixon' and a collection of D1015 Western Champion, Paul Barlow.

Item 2111 'G7 and all that'. A collection of pictures of railway happenings associated with the conference at Carbis Bay in early June.

Item 2112 Railtours into Cornwall Spring and early Summer 2021

Item 2113 THE GRANGE CLASS of the GWR An article by Michael L. Roach

Item 2114 Royal Train Formation 11th June 2021 An article by Guy Vincent.

Item 2114

Royal Train Formation 11th June 2021

An article by Guy Vincent.

Royal Train Formation 11th June 2021

An article by Guy Vincent.

Following the recent visit of the Royal Train to Cornwall it is perhaps an appropriate time to take a closer look at the formation and vehicles used.

1Z95 1210 Windsor & Eton Riverside - St Austell was formed : 67006 2921 2903 2904 2922 2923 2916 2917 2915 2920 10546 67005

1) 2921 Royal Household Couchette, Kitchen and Bathroom. Previous numbers 14107 17107 Converted 1986

2) 2903 HM The Queen's Lounge, Bedroom & Bathroom. Previous number 11001 (TF) Built 1972 as part of the prototype HST set 252001. Converted in 1977.

3) 2904 HRH The Duke of Edinburgh's Lounge, Bedroom & Bathroom. Previous number 12001 (TS) Built 1972 as part of the prototype HST set 252001. Converted in 1977.

4) 2922 HRH The Prince of Wales's Sleeping Car. Purpose-built in 1987

5) 2923 HRH The Prince of Wales's Saloon. Purpose-built in 1987

6) 2916 Royal Family Dining Car / Kitchen. Previous number 40512 (TRFK) Converted 1986

7) 2917 Royal Household Dining Car / Kitchen. Previous Number 40514 (TRFK) Converted 1986

8) 2915 Royal Household Sleeping Car. Previous Number 10735. Converted 1985

9) 2920 Royal Household Couchette Diesel Generator & Brake Van. Previous Numbers 14109 17109 Converted 1986

10) 10546 Sleeping Car DB Cargo Owned

The train made a delightful sight as it made its way west through the Somerset countryside. Sadly for linesiders the return was under cover of darkness although an hours break was taken at Westbury where the water tanks on the coaches were replenished.

Photo of full train headed by 67006 taken by Cathy V. Remainder (of the stock passing Berkley Marsh) taken by myself. Final image of the return in P2 at Westbury taken by 'A.Driver' who wishes to remain anonymous.

Best regards

Guy Vincent.

1Z95 1210 Windsor & Eton Riverside - St Austell was formed : 67006 2921 2903 2904 2922 2923 2916 2917 2915 2920 10546 67005

1) 2921 Royal Household Couchette, Kitchen and Bathroom. Previous numbers 14107 17107 Converted 1986

2) 2903 HM The Queen's Lounge, Bedroom & Bathroom. Previous number 11001 (TF) Built 1972 as part of the prototype HST set 252001. Converted in 1977.

3) 2904 HRH The Duke of Edinburgh's Lounge, Bedroom & Bathroom. Previous number 12001 (TS) Built 1972 as part of the prototype HST set 252001. Converted in 1977.

4) 2922 HRH The Prince of Wales's Sleeping Car. Purpose-built in 1987

5) 2923 HRH The Prince of Wales's Saloon. Purpose-built in 1987

6) 2916 Royal Family Dining Car / Kitchen. Previous number 40512 (TRFK) Converted 1986

7) 2917 Royal Household Dining Car / Kitchen. Previous Number 40514 (TRFK) Converted 1986

8) 2915 Royal Household Sleeping Car. Previous Number 10735. Converted 1985

9) 2920 Royal Household Couchette Diesel Generator & Brake Van. Previous Numbers 14109 17109 Converted 1986

10) 10546 Sleeping Car DB Cargo Owned

The train made a delightful sight as it made its way west through the Somerset countryside. Sadly for linesiders the return was under cover of darkness although an hours break was taken at Westbury where the water tanks on the coaches were replenished.

Photo of full train headed by 67006 taken by Cathy V. Remainder (of the stock passing Berkley Marsh) taken by myself. Final image of the return in P2 at Westbury taken by 'A.Driver' who wishes to remain anonymous.

Best regards

Guy Vincent.

Many thanks to Guy and Cathy Vincent

Item 2113

THE GRANGE CLASS of the GWR Michael L. Roach

A useful mixed traffic class

THE GRANGE CLASS of the GWR Michael L. Roach

A useful mixed traffic class

THE GRANGE CLASS of the GWR Michael L. Roach

A useful mixed traffic class

The Grange class was introduced by the Great Western Railway in 1936 and the design was derived from the Churchward Moguls of 1911 and shared many components with the Hall Class of 1928. All the main dimensions and fittings were similar to the Hall Class except that the diameter of the driving wheels was reduced by 4 inches (101.6mm). This gave a useful increase in tractive effort of 6 percent but more importantly gave the Grange class better hill-climbing abilities. The class proved particularly useful on lines with switchback gradients like the Cornish main line. Of the 258 Hall class many entered preservation soon after withdrawal from British Railways and many later from Barry scrapyard. Of the 80 Grange class built every single one was withdrawn and cut up leaving none in preservation; however this gap is now being filled with the construction of the 81st Grange by the Betton Grange Society. In this short feature we will see four examples of the class on typical duties in Devon and Cornwall in the summer of 1961. In the last picture we see 6860 waiting to take over a train at Plymouth Station. I travelled on the train as far as Bodmin Road and it kept time with 12 coaches weighing in the region of 420 tons. The train was allowed three hours to reach Penzance and the limit for a Grange over the route was 385 tons.

MLR/ 27 May 2021

A useful mixed traffic class

The Grange class was introduced by the Great Western Railway in 1936 and the design was derived from the Churchward Moguls of 1911 and shared many components with the Hall Class of 1928. All the main dimensions and fittings were similar to the Hall Class except that the diameter of the driving wheels was reduced by 4 inches (101.6mm). This gave a useful increase in tractive effort of 6 percent but more importantly gave the Grange class better hill-climbing abilities. The class proved particularly useful on lines with switchback gradients like the Cornish main line. Of the 258 Hall class many entered preservation soon after withdrawal from British Railways and many later from Barry scrapyard. Of the 80 Grange class built every single one was withdrawn and cut up leaving none in preservation; however this gap is now being filled with the construction of the 81st Grange by the Betton Grange Society. In this short feature we will see four examples of the class on typical duties in Devon and Cornwall in the summer of 1961. In the last picture we see 6860 waiting to take over a train at Plymouth Station. I travelled on the train as far as Bodmin Road and it kept time with 12 coaches weighing in the region of 420 tons. The train was allowed three hours to reach Penzance and the limit for a Grange over the route was 385 tons.

MLR/ 27 May 2021

4923 6860 Aberporth Grange is seen at Plymouth Station at about 1.30pm on 5 August 1961. The loco is waiting to take over the 7.25am Ealing Broadway to Penzance which was running half an hour late. The loco had arrived at Laira Shed two months earlier and was stored the following month. Copyright Michael L. Roach

Many thanks Mike

Railtours to Cornwall & Devon

Spring and early Summer 2021

Railtours to Cornwall & Devon

Spring and early Summer 2021

Devon Express Charter

9th June 2021

9th June 2021

LMS 4-6-0 46100 'Royal Scot' and LMS Stanier 4-6-0 Black Five 45231 'The Sherwood Forester' with 47614 on the rear with the 1Z70 06.00 Solihull - Plymouth charter operated by Saphos Train returning with the delayed 1Z72 17.00 Plymouth - Solihull. The first two pictures are at Langford Bridge just west of what was Aller Junction at 13.30. Although overcast there was a bit of brightness unlike at Brent at 17.37 in the third picture which can best be described as 'dreich'. Irrespective of the weather these were a magnificent sight.

Regards. Clive Smith.

Regards. Clive Smith.

Turning the train at :Laira

The returning charter:-

Royal Scot to Paignton & Kingswear

Saturday 6th June 2021

Saturday 6th June 2021

The run to Paignton.

The return working.

The Statesman

Wednesday 2nd June 2021

Wednesday 2nd June 2021

Wolverhampton to Penzance

Taunton

Evening Keith/Roger

Taken yesterday at Taunton, 1Z45 05.10 Wolverhampton-Penzance 'Cornish Statesman Pullman' with 47593 & 47614 from the replacement '50 Steps' footbridge (2.6.2021).

All the Best

Andrew

Evening Keith/Roger

Taken yesterday at Taunton, 1Z45 05.10 Wolverhampton-Penzance 'Cornish Statesman Pullman' with 47593 & 47614 from the replacement '50 Steps' footbridge (2.6.2021).

All the Best

Andrew

Here are my offerings. Thankfully the rain held off but dull skies all round. I went to Totnes hoping the tour's booked stop on the through road would happen giving me the chance of two shots instead of hammering through. Luckily it did stop. I also managed a return shot at Newton Abbot.

Hope you are well. Regards to Keith.

All the best

Copyright Clive Smith

The Cornish Riviera Statesman - the return journey

The Blue Pullman

Saturday 29th May 2021

Saturday 29th May 2021

Many thanks to all our contributors photographing this remarkable

Midland Blue Pullman

Bob Morrison Bill Elston Andrew Triggs Paul Barlow Keith Turley

Peter Murnaghan Adrian Keast Nathen Hadley Craig Munday

Mike Paterson Neville King Martin Scane Mick House Lana Harris

Leslie Curnow Mike Bojko Roger Salter Mark Lynam David Tozer

& Guy & Charlotte Vincent

Many Thanks Roger Winnen

Midland Blue Pullman

Bob Morrison Bill Elston Andrew Triggs Paul Barlow Keith Turley

Peter Murnaghan Adrian Keast Nathen Hadley Craig Munday

Mike Paterson Neville King Martin Scane Mick House Lana Harris

Leslie Curnow Mike Bojko Roger Salter Mark Lynam David Tozer

& Guy & Charlotte Vincent

Many Thanks Roger Winnen

The journey down

Some detailed information on the Blue Pullman by Guy Vincent with photographs at Melksham on the outward run and Westbury on the return run.

Many Thanks Guy for your detailed information

The Pullman was formed of vehicles 43055 41176 41108 40802 41162 41059 41182 40801 41169 44078 43046.

The two power cars were delivered new to the Western Region in 1977 as part of sets 253023 (43046) and 253027 (43055, the last of the initial batch). By October1981 had BR decided several of these sets were no longer needed on the WR so 253027 was transferred away to Neville Hill (Leeds) for use on the East Coast Main Line. October 1982 saw another five sets leave for use on the Midland Main Line between St Pancras and Sheffield, these were 253022 - 253026 inclusive (power cars 43044-43053). May 1983 and another three WR sets departed with two (253019 / 253020, power cars 43038-41) going to Neville Hill and 253021 (PCs 43042/043) transferring to Bounds Green. Over the years reallocations and a common use policy has seen some of the older PCs return to their former haunts but for 43046 & 43055 this was a welcome return to old and much changed home territory.

The only previous occasion an HST is known to have stopped at Melksham was on Sunday 5th December 2010. Then, the 1705 Westbury - Swindon and 2M16 1819 Swindon - Westbury were unusually worked by 43069, set OC46 and 43088. This was because the normal DMU (150129) could not be strengthened and over 100 tickets had been pre-booked from Trowbridge and Melksham to Swindon and back as the service was used for the annual Melksham Rail Users Group / Trans Wilts ''Santa Special''.

Best regards Guy Vincent

The two power cars were delivered new to the Western Region in 1977 as part of sets 253023 (43046) and 253027 (43055, the last of the initial batch). By October1981 had BR decided several of these sets were no longer needed on the WR so 253027 was transferred away to Neville Hill (Leeds) for use on the East Coast Main Line. October 1982 saw another five sets leave for use on the Midland Main Line between St Pancras and Sheffield, these were 253022 - 253026 inclusive (power cars 43044-43053). May 1983 and another three WR sets departed with two (253019 / 253020, power cars 43038-41) going to Neville Hill and 253021 (PCs 43042/043) transferring to Bounds Green. Over the years reallocations and a common use policy has seen some of the older PCs return to their former haunts but for 43046 & 43055 this was a welcome return to old and much changed home territory.

The only previous occasion an HST is known to have stopped at Melksham was on Sunday 5th December 2010. Then, the 1705 Westbury - Swindon and 2M16 1819 Swindon - Westbury were unusually worked by 43069, set OC46 and 43088. This was because the normal DMU (150129) could not be strengthened and over 100 tickets had been pre-booked from Trowbridge and Melksham to Swindon and back as the service was used for the annual Melksham Rail Users Group / Trans Wilts ''Santa Special''.

Best regards Guy Vincent

The journey back

Item 2111

'G7 and all that'.

A collection of pictures of railway happenings associated with the conference at Carbis Bay in early June.

'G7 and all that'.

A collection of pictures of railway happenings associated with the conference at Carbis Bay in early June.

The Closure Notice for the St Ives branch for the G7 week.

I suspect we all know the reason for this one:

..................................................................................................

From the Western and Wales Route Weekly Operating Notice WW Week 10

GW690 ST.ERTH TO ST.IVES ENTIRE LINE OF ROUTE FROM 0001 MONDAY 7 JUNE 2021 UNTIL 1200 HOURS ON MONDAY

14 JUNE 2021

The St.Ives single line beyond St.Erth signal SE62 will be temporarily taken out of use. The St.Erth – St.Ives train staff will be retained by the local manager. The associated Local Instructions are suspended during this time.

............................................................................................

Kind Regards,

Chris Bellett

Retired S&T Engineer

..................................................................................................

From the Western and Wales Route Weekly Operating Notice WW Week 10

GW690 ST.ERTH TO ST.IVES ENTIRE LINE OF ROUTE FROM 0001 MONDAY 7 JUNE 2021 UNTIL 1200 HOURS ON MONDAY

14 JUNE 2021

The St.Ives single line beyond St.Erth signal SE62 will be temporarily taken out of use. The St.Erth – St.Ives train staff will be retained by the local manager. The associated Local Instructions are suspended during this time.

............................................................................................

Kind Regards,

Chris Bellett

Retired S&T Engineer

One wonders whether the VOSE Pullman will be providing a service over the branch during the week?

Cheap at much less than half the price!!!

Prices to stay at one of the hotels used for the G7 Leader's Summit after the event in Cornwall this year have skyrocketed.

In order to enjoy one of the Carbis Bay Hotel's three-bedroom villa's between the June 17-23, a week after the G7 Summit, you'll need to be ready to part with £4,000 per night - a £24,000 total stay.

The hotel's two bedroom villa comes in shorter at £21,000 for the six night stay.

According to the hotel's website, the villas also come with free breakfast and WiFi, too.

In order to enjoy one of the Carbis Bay Hotel's three-bedroom villa's between the June 17-23, a week after the G7 Summit, you'll need to be ready to part with £4,000 per night - a £24,000 total stay.

The hotel's two bedroom villa comes in shorter at £21,000 for the six night stay.

According to the hotel's website, the villas also come with free breakfast and WiFi, too.

Tidying up for G7 Andrew Triggs

After being on Sandy Road siding, Ponsandane since 1988, today (3rd April 2021) a start has been made on breaking up the 2 former fuel tankers there, 5 shots for CRS enclosed

All the Best

Andrew Triggs

It is understood that this is part of the tidy up operation before the G7 VIP's arrive.

All the Best

Andrew Triggs

It is understood that this is part of the tidy up operation before the G7 VIP's arrive.

Many thanks Andrew - a colourful piece of Penzance has gone.

28th April 2021

Residents in St Ives and Carbis Bay are dismayed – and perplexed – about the large number of police in the area in the run-up to the G7 Summit.

Large number of officers in baseball-style caps and yellow jackets have been seen on the streets in west Cornwall in recent days.

They have been witnessed on their hands and knees inspecting drains and manhole covers as well as lamp posts and other street furniture, often accompanied by police dogs.

Residents in St Ives and Carbis Bay are dismayed – and perplexed – about the large number of police in the area in the run-up to the G7 Summit.

Large number of officers in baseball-style caps and yellow jackets have been seen on the streets in west Cornwall in recent days.

They have been witnessed on their hands and knees inspecting drains and manhole covers as well as lamp posts and other street furniture, often accompanied by police dogs.

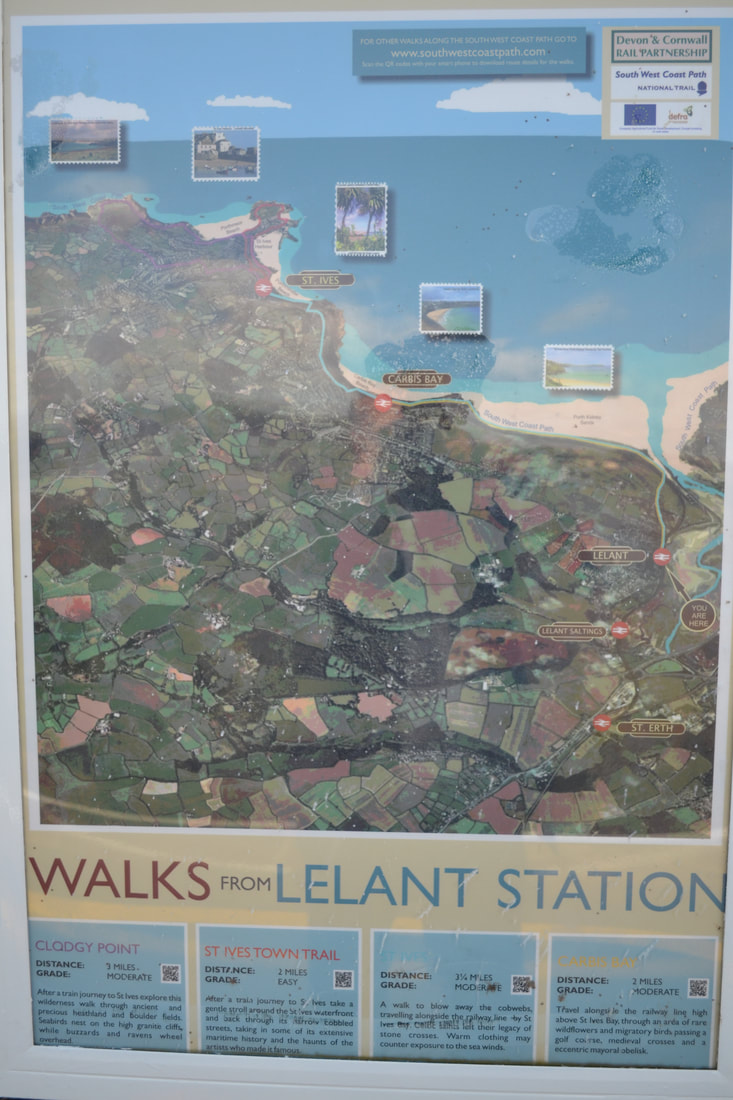

Roger Winnen takes a trip on the branch in April.

On Monday 25th April Roger Winnen took a trip on the St Ives branch to see what could be seen from the train - unfortunately Rogers pictures were limited to what could be seen from the train as the preparation work for the G7 conference continues without planning permission.

Links

Links

Roger also reports that some re-surfacing work had taken place at both Carbis Bay and St Ives stations.

Special Test Train for G7 run over the St Ives branch.

A special Pullman train ran to Penzance on the 21st April the purpose of which we heard afterwards was to check the clearances etc on the St Ives Branch. The down train didn't appear in the Real Time Trains at all as it was to be regarded as SECRET !

The stock was worked overnight 21/22nd April over the St Ives branch - we do not have any pictures of this most unusual working.

The return working the 22nd April appeared in Real time Trains.

The stock was worked overnight 21/22nd April over the St Ives branch - we do not have any pictures of this most unusual working.

The return working the 22nd April appeared in Real time Trains.

In the course of a brief swing through your lovely county I spotted Roger's pictures on CRS and hastened to record "the other end" as the train returned to London. Here attached is a shot of the VSOE Pullman Train heading for the Red River Viaduct North of Marazion. 67012, formerly "Shropshire Lad" and now in Chiltern Railways' 2-tone grey leads the train with 67016 in the rear. The train left Penzance at 18.00 for Stewarts Lane Depot and is recorded here a few minutes later. Copyright Brian Pibworth

Roger Winnen takes a trip on The St Ives Branch

Bank Holiday Monday 31st May 2021

Bank Holiday Monday 31st May 2021

Lelant Station 3rd June 2021

Roger Winnen

Roger Winnen

Lelant Saltings Station

A visit to Lelant Saltings Station this afternoon, was a non event as a large compound has been erected around most of the site guarded by Police Officers. They were aware that trains stopped there at 07.52 to St Ives and 09.21 to St Erth, no doubt special arrangements were in place for any passengers joining or alighting from trains

A visit to Lelant Saltings Station this afternoon, was a non event as a large compound has been erected around most of the site guarded by Police Officers. They were aware that trains stopped there at 07.52 to St Ives and 09.21 to St Erth, no doubt special arrangements were in place for any passengers joining or alighting from trains

A Visit to St Ives and St Erth Station on Tuesday 8th June 2021

Roger Winnen

Roger Winnen

St Erth Station Thursday 10th June 2021

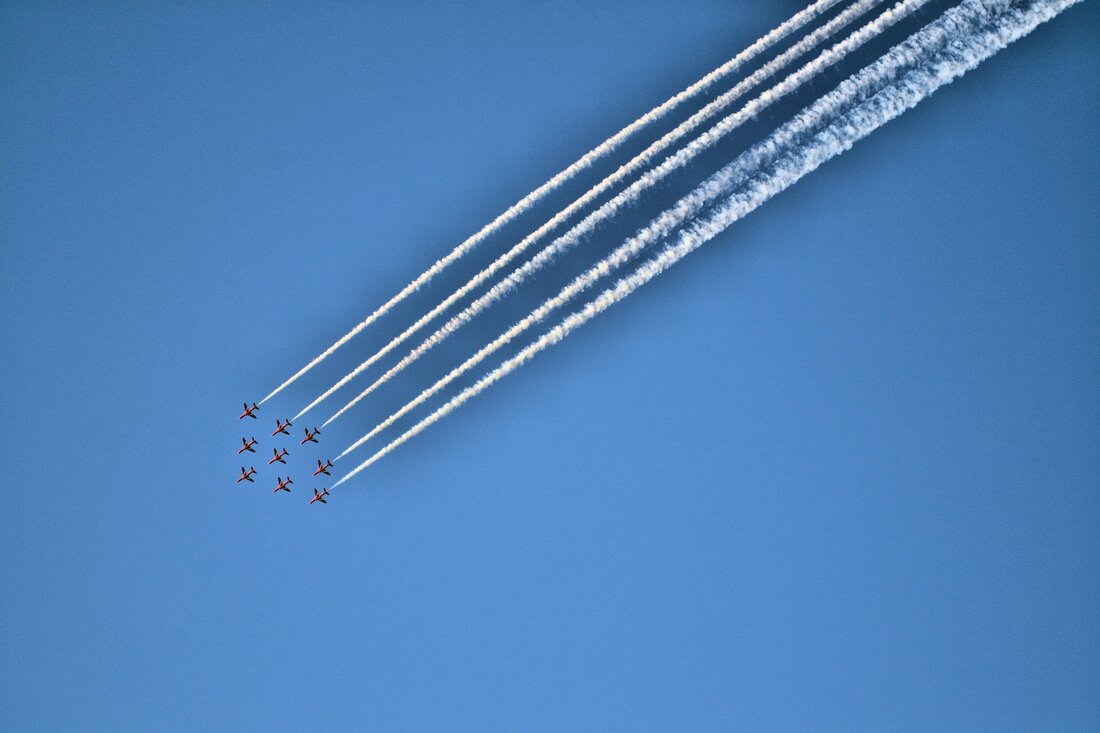

The Red Arrows arrive at St Ives and Carbis Bay on Saturday evening 12th June 2021 to entertain the G7 Conference and the people of West Cornwall. Earlier in the day they were seen flying over Windsor Castle for the Queens Official Birthday celebrations of Trooping the Colour

Roger Winnen

Roger Winnen

Item 2110

The story of 'Ixion',plus feature on D1015 Western Champion

Paul Barlow

The story of 'Ixion',plus feature on D1015 Western Champion

Paul Barlow

A set of pictures of D172 Ixion's visit to Penzance on 23 September 1995

This loco was owned by Waterman Railways and was the first preserved diesel to work on the mainline. It received a full restoration at Crewe in 1994. It made it's inaugral main-line run from Derby to St Pancras on 1 October 1994. In BR days this loco was 46035 and spent most of it's life allocated to (GD) Gateshead, Newcastle. Upon withdrawal from BR service it was used by Derby research centre for various tests as a adhesion research vehicle, this where it received the 'Ixion' name and numbered 97403.

It was repainted in BR blue in 2002 and renumbered 46035

Sadly the loco fell out of use in 2004 and was eventually sold. It is now in store awaiting restoration at Peak rail Rowsley, Derbyshire

Hope all is well, Kind regards

Paul Barlow

This loco was owned by Waterman Railways and was the first preserved diesel to work on the mainline. It received a full restoration at Crewe in 1994. It made it's inaugral main-line run from Derby to St Pancras on 1 October 1994. In BR days this loco was 46035 and spent most of it's life allocated to (GD) Gateshead, Newcastle. Upon withdrawal from BR service it was used by Derby research centre for various tests as a adhesion research vehicle, this where it received the 'Ixion' name and numbered 97403.

It was repainted in BR blue in 2002 and renumbered 46035

Sadly the loco fell out of use in 2004 and was eventually sold. It is now in store awaiting restoration at Peak rail Rowsley, Derbyshire

Hope all is well, Kind regards

Paul Barlow

Plus a short feature on

D1015 Western Champion by Paul Barlow

D1015 Western Champion by Paul Barlow

A few shots of D1015 Western Champion in Golden ochre livery around the Exeter area in early summer 2005. Hopefully one day we will see this fine locomotive on the main line again!

Kind regards, Paul

Kind regards, Paul

Many thanks Paul for the 'double bill' 'Ixion' and 'Champion'.

Item 2109

The 'Private Charter'

to and from Penzance

4th, 5th and 6th April 2021.

The 'Private Charter'

to and from Penzance

4th, 5th and 6th April 2021.

Sunday 4th April. Bristol to Penzance.

Monday 5th April Penzance to Truro

Truro to Plymouth, Laira Depot, Newton Abbot and Kingswear

I must be the only person to have taken the return working in cloud, although bitterly cold I chose to walk to Par station being local, at the booked time the signal box was bathed in sunlight but with the train running 15 minutes late it clouded over and 37667 is seen in the middle of a snow storm passing Par Signal Box, top and tailed 37688 'Great Rocks' working 1Z33 to Plymouth and on to Laira on 6th April 2021

Copyright Alan Peters

Wednesday 7th April 2021 Kingswear to London Euston

Many thanks to all our contributors.

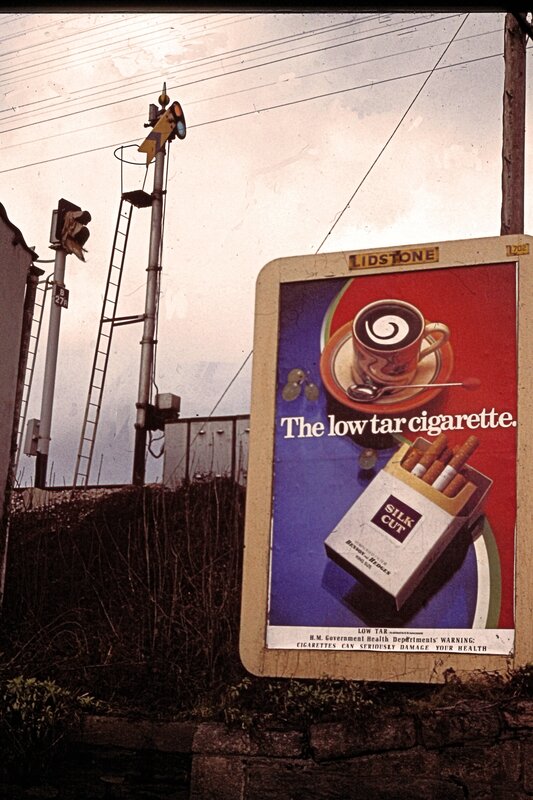

Item 2108

The closure of

Newquay signalbox

- a photographic record by Alan Peters and Gary Rainbow.

The closure of

Newquay signalbox

- a photographic record by Alan Peters and Gary Rainbow.

Some pictures taken by myself and friend Gary Rainbow of the Closure of Newquay Signal Box, although the official date of closure was the 5th October 1987, the last train must have been Saturday 3rd October. The night was spent in the PW hut at the end of the platform as official permission was given to recover signalling equipment from Newquay by BR, the equipment was decommissioned on the Sunday by the S&T and the main signal dismantled for restoration by the late Bernard Rainbow MBE. The Signal Box was retained as a traincrew mess room until being torched by vandals bringing the end of an era to Newquay's fine semaphore signals, fortunately the main signal that once protected the station has been restored to its former glory at a private address in Birmingham.

Alan Peters

Alan Peters

Newquay Signal Box closed on the 5th October 1987, these pictures were taken on that very evening when the box would close for the final time after the last train, a last look at Newquay Signal Box with it's semaphore signals, No 1 signal had already lost it's finial and the trackwork looking rather rusty! Copyright Alan Peters

Ref The most interesting feature by Alan Peters The photograph of the Electric Key Token instrument shows green (‘C’ configuration’) tokens. Now ‘C’ tokens were used for the single-line section from Newquay to St Columb Road which came into existence after the closure of Tolcarn Junction in November 1964. After the closure of St Columb Road in January 1965 the section then became Newquay to St Dennis Junction using yellow (‘D’ configuration) tokens until the closure of St Dennis Junction in December 1986. At that time the St Dennis Junction to Goonbarrow Junction section used ‘C’ tokens, but what I do not know is whether the new Goonbarrow Junction to Newquay section then used ‘C’ or ‘D’ tokens until Newquay closed in October 1987. As I can’t read the wording on the tokens, I would be very interested therefore to know if that photograph is from the 1964-65 or 1986-1987 period please.

Kind regards, Chris Osment

Kind regards, Chris Osment

Alan Peters replies - Hi Keith,

All the pictures were taken at the time of the closure of the signal box in October 1987, I believe the tokens are Newquay - Goonbarrow Jct, the token instrument was the first thing to be removed by the S&T when the box closed and there was me hoping for a souvenir, however number 15 lever plate for the ground frame had to suffice. I Understand that the ground frame was moved for a short period for a siding, which I have no idea if it was ever used. I think the section is still a green token, which I thought I had a picture of the token somewhere, maybe Craig can confirm as I don't get up there too often.

I used to own the ground signal from the carriage sidings but had to sell it when I moved briefly to Australia something I very much regret as I doubt I will get another.

Gary Rainbow is now the Driver Standards manager for Cross Country Trains.

Regards Alan Peters

All the pictures were taken at the time of the closure of the signal box in October 1987, I believe the tokens are Newquay - Goonbarrow Jct, the token instrument was the first thing to be removed by the S&T when the box closed and there was me hoping for a souvenir, however number 15 lever plate for the ground frame had to suffice. I Understand that the ground frame was moved for a short period for a siding, which I have no idea if it was ever used. I think the section is still a green token, which I thought I had a picture of the token somewhere, maybe Craig can confirm as I don't get up there too often.

I used to own the ground signal from the carriage sidings but had to sell it when I moved briefly to Australia something I very much regret as I doubt I will get another.

Gary Rainbow is now the Driver Standards manager for Cross Country Trains.

Regards Alan Peters

Many thanks to Alan Peters and of course to Gary Rainbow for this marvelous record of changes at Newquay.

Additional Info - a footnote from Roy Hart (Burma).

Alan Peters and Gary Rainbow may be interested in the following:

Newquay box dated from 1946. It was the last new box erected in Cornwall. By the time of its closure, much of the layout had already been stripped out, including six carriage sidings, the goods yard and the engine loop on platform 3.

The 'signal protecting the station' is the down inner home. It was erected in 1959, replacing a wooden signal of 1946. It originally carried 5 route indicator positions: plat 1; plat 2; plat 3; loco spur; sidings.

The token machine in the box was fitted in 1964 when, with the closure of Tolcarn Junction box, the line into Newquay became single track.

Roy Hart Many thanks Roy.

Alan Peters and Gary Rainbow may be interested in the following:

Newquay box dated from 1946. It was the last new box erected in Cornwall. By the time of its closure, much of the layout had already been stripped out, including six carriage sidings, the goods yard and the engine loop on platform 3.

The 'signal protecting the station' is the down inner home. It was erected in 1959, replacing a wooden signal of 1946. It originally carried 5 route indicator positions: plat 1; plat 2; plat 3; loco spur; sidings.

The token machine in the box was fitted in 1964 when, with the closure of Tolcarn Junction box, the line into Newquay became single track.

Roy Hart Many thanks Roy.

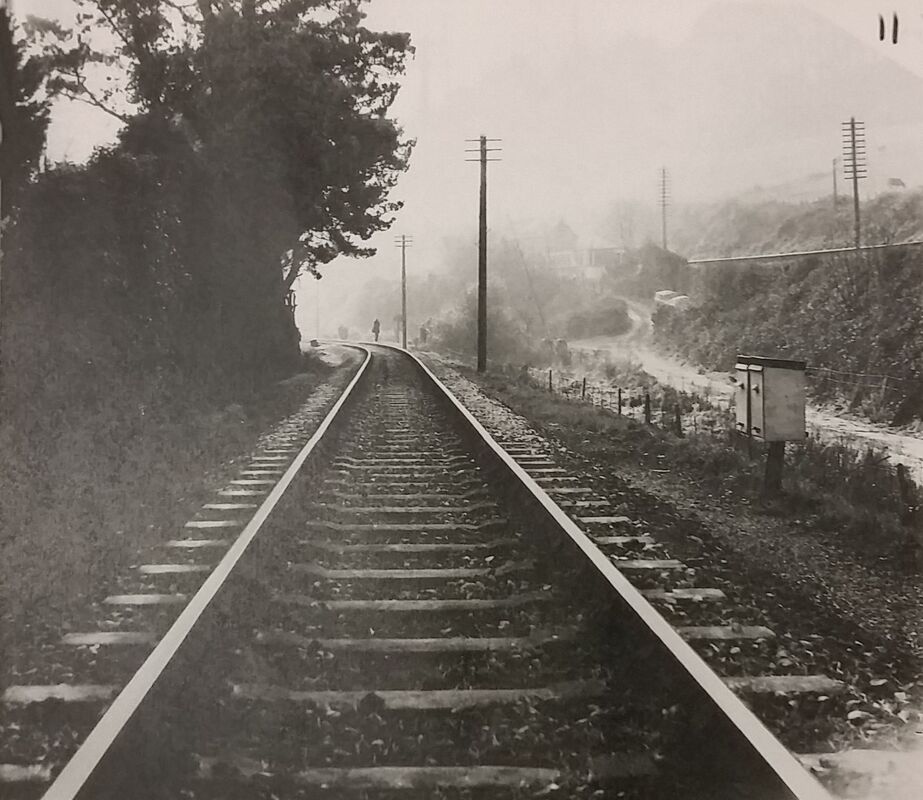

Item 2107

Accident on the Fowey branch

Monday 6th December 1971

A report compiled by Guy Vincent

Accident on the Fowey branch

Monday 6th December 1971

A report compiled by Guy Vincent

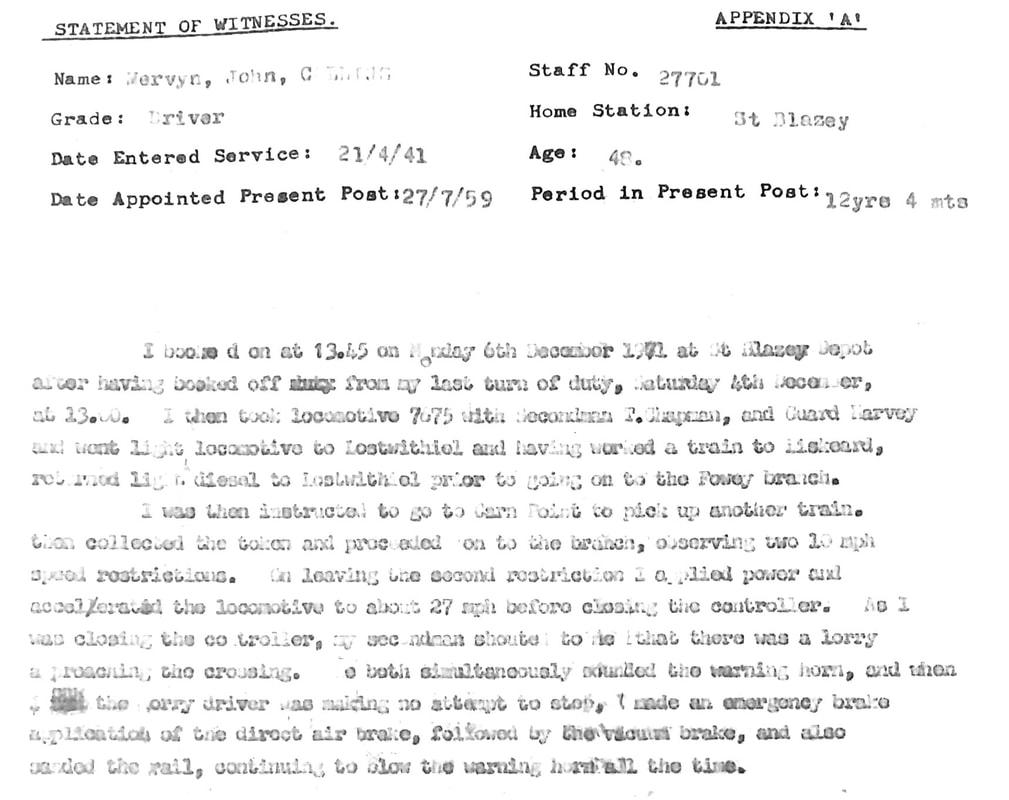

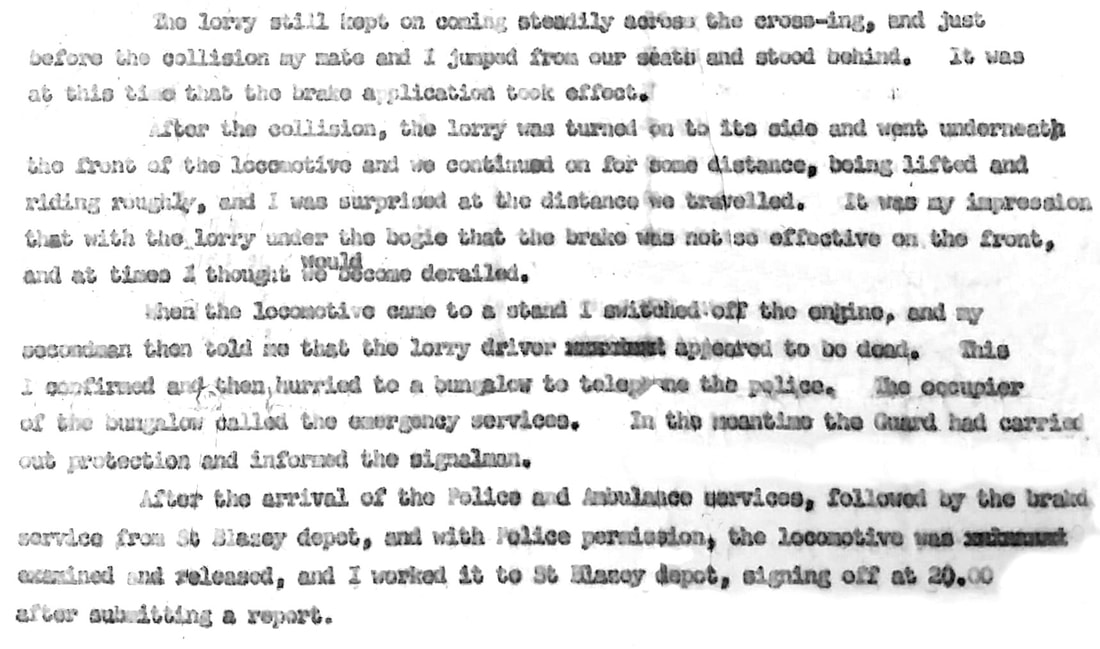

Guy Vincent writes :- The information on the Fowey branch incident was provided by one of my colleagues at Westbury who happens to be a grandson of the driver of the class 25 loco involved. Last year (2020) he was given a box of railway documents that had belonged to his late grandfather, these had apparently been stored for a long time in the loft of another family member's home. The report of the incident was with these documents and the family are happy for this to be published on the CRS site.

Driver Mervyn John Collins was born in the Liskeard district in 1923 and started his railway service with the GWR in 1941. He became a driver at St Blazey in 1959 and apart from a few years at Westbury (Wilts) his career was spent close to home in Lostwithiel, Cornwall. Mervyn retired in 1988 and passed away on 17th January 2008 at the age of 84. He was for many years involved with the Lostwithiel Silver Band.

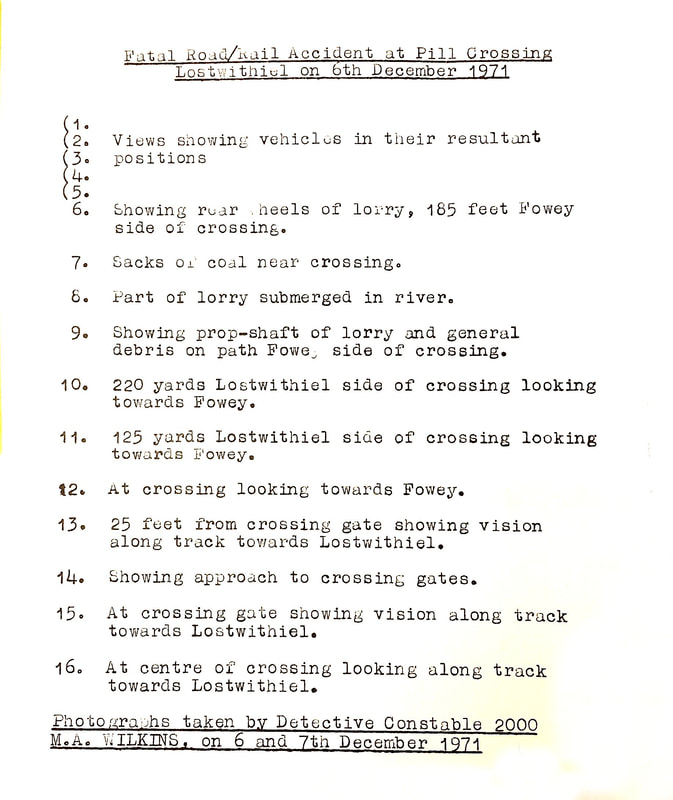

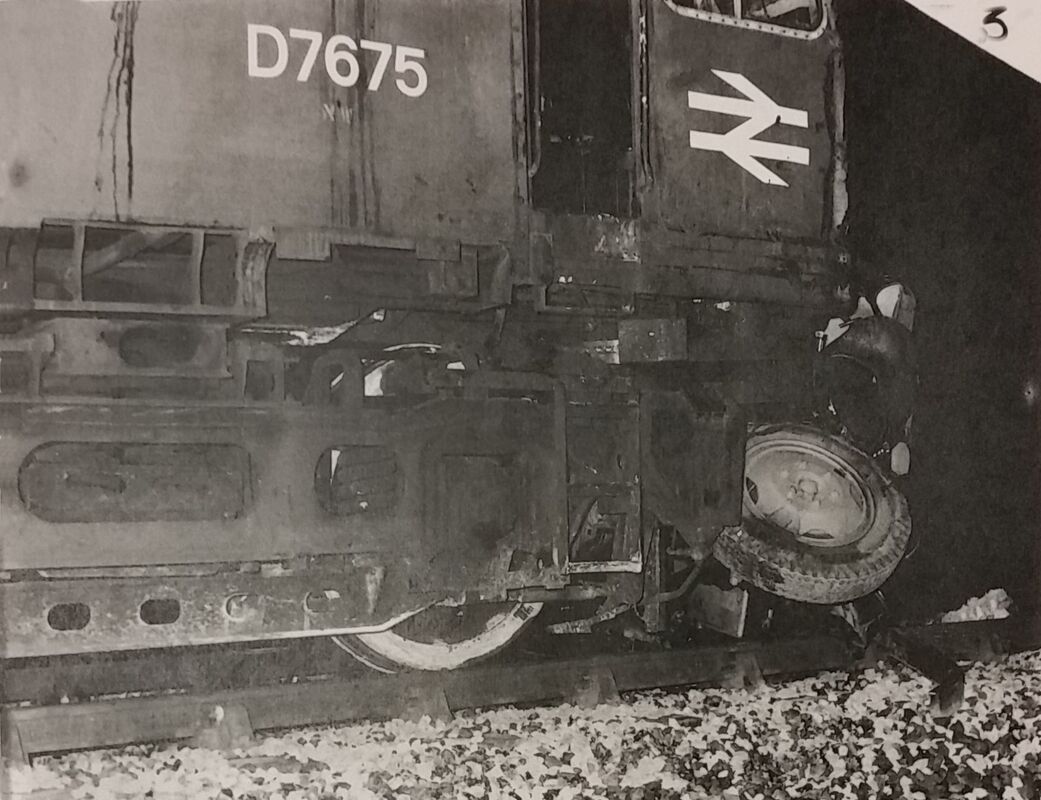

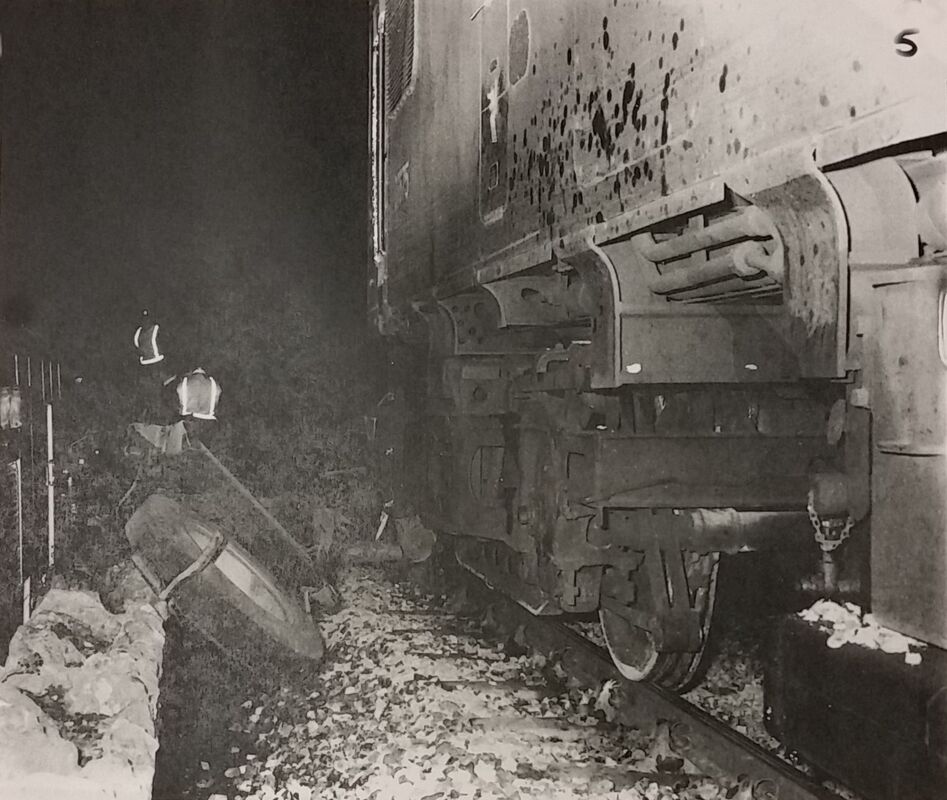

Class 25 locomotive D7675 was delivered new to the Nottingham Division (D16) on April 8th 1967, one of the final members of the 327-strong class to be built. In October 1971 it was transferred to Laira (84A) and moved to Cardiff Canton (86A) in May of the following year. On 13th May 1974 it was renumbered 25325 and lasted in service until withdrawal from Holbeck, Leeds on 24.12.1985. It was scrapped by MC Metals at Glasgow in February 1990. See the excellent 'Derby Sulzers' website for more details not only of this loco but all Sulzer powered BR diesels.

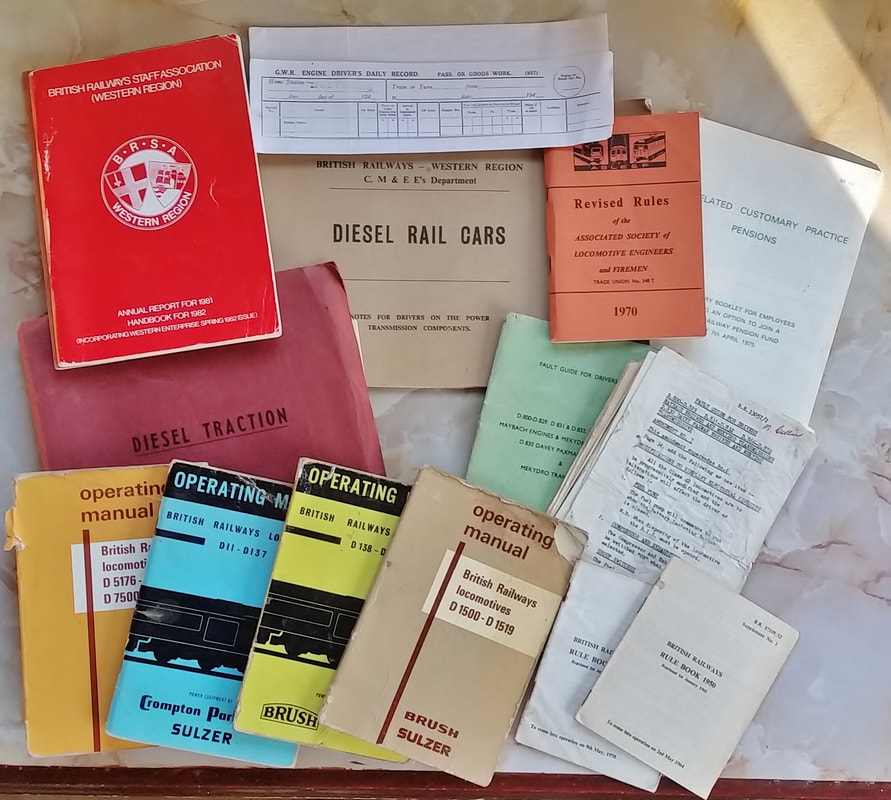

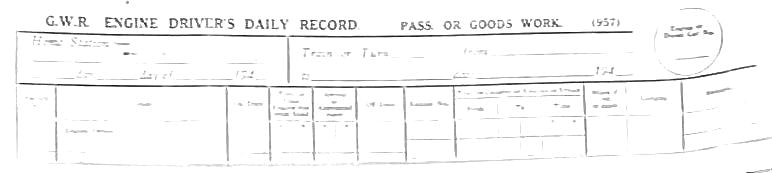

Here's an image of the other railway documents, all well-used, that were in driver Collins' possession.

They and the photographs are now in the custody of Mervyn's grandson, Darren, who is a driver colleague of mine at Westbury and he is pleased that the feature has been published.

Regards for now

Guy

Driver Mervyn John Collins was born in the Liskeard district in 1923 and started his railway service with the GWR in 1941. He became a driver at St Blazey in 1959 and apart from a few years at Westbury (Wilts) his career was spent close to home in Lostwithiel, Cornwall. Mervyn retired in 1988 and passed away on 17th January 2008 at the age of 84. He was for many years involved with the Lostwithiel Silver Band.

Class 25 locomotive D7675 was delivered new to the Nottingham Division (D16) on April 8th 1967, one of the final members of the 327-strong class to be built. In October 1971 it was transferred to Laira (84A) and moved to Cardiff Canton (86A) in May of the following year. On 13th May 1974 it was renumbered 25325 and lasted in service until withdrawal from Holbeck, Leeds on 24.12.1985. It was scrapped by MC Metals at Glasgow in February 1990. See the excellent 'Derby Sulzers' website for more details not only of this loco but all Sulzer powered BR diesels.

Here's an image of the other railway documents, all well-used, that were in driver Collins' possession.

They and the photographs are now in the custody of Mervyn's grandson, Darren, who is a driver colleague of mine at Westbury and he is pleased that the feature has been published.

Regards for now

Guy

***To see somewhat more recent pictures of the line at the accident location please go to the end of this section.

The Statement made by Mervyn John Collins

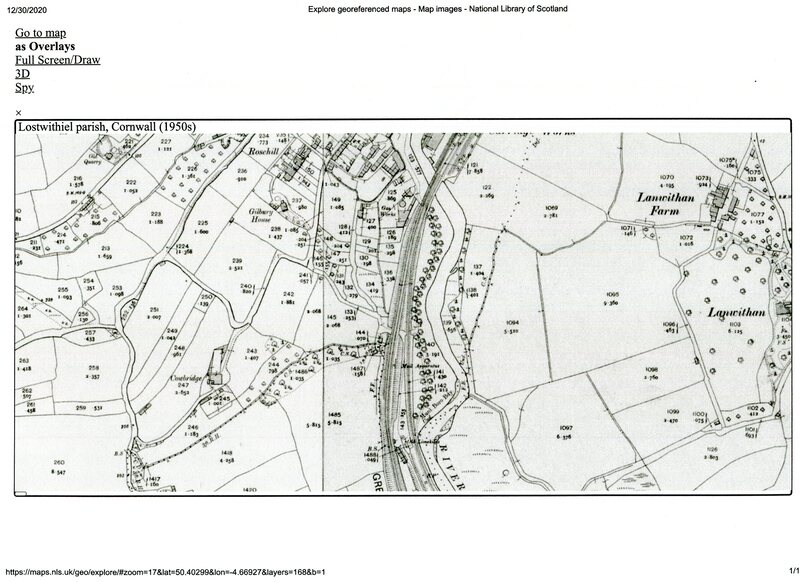

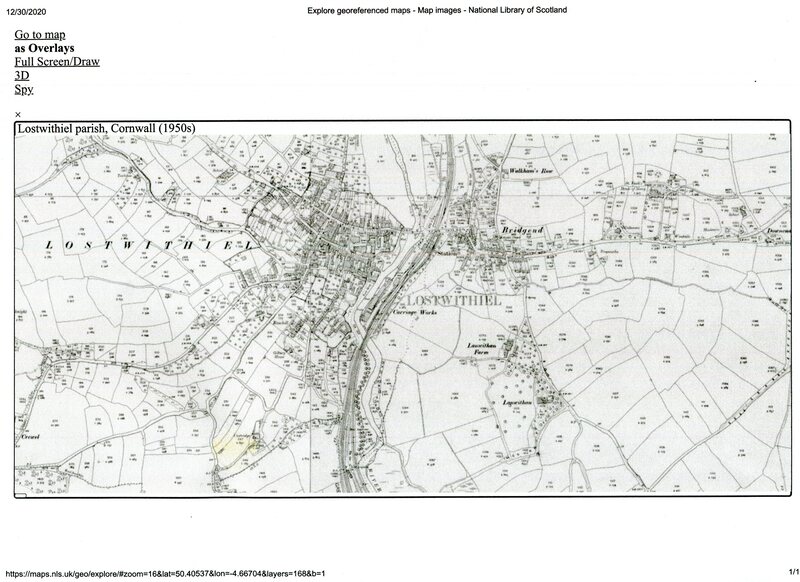

Pill Farm Crossing is at about the centre of this map - the lane continues to the left to Pill Farm and under the main line which crosses it by means of an overbridge. This map is an enlargement from the map belowMap from the 25" OS reproduced for non commercial purposes courtesy of the National library of Scotland.

From a 25" OS Map revised to the 1950's Showing the Fowey branch leaving Lostwithiel taking an independent bridge over the river Fowey. This route was abolished in 1972 when the branch was altered to connect to the down main.

Map from the 25" OS reproduced for non commercial purposes courtesy of the National library of Scotland.

.Many thanks Guy - what interesting things you come across. Also thank you to Darren who made the reports and images available to the CRS.

***To see somewhat more recent pictures of the line at the level crossing please see below.

Pictures by Roger Winnen

Pictures by Roger Winnen

A series of passenger trains were run by the

Lostwithiel Chamber of Commerce to

Carne Point on the 9th April 1994.

Lostwithiel Chamber of Commerce to

Carne Point on the 9th April 1994.

Many thanks to Roger for providing pictures of this event in 1994.

Item 2106

The purpose of this section is to look at various operations at St Austell station and look at traffic to the goods yard and finally the removal of the goods branch

Item 2106

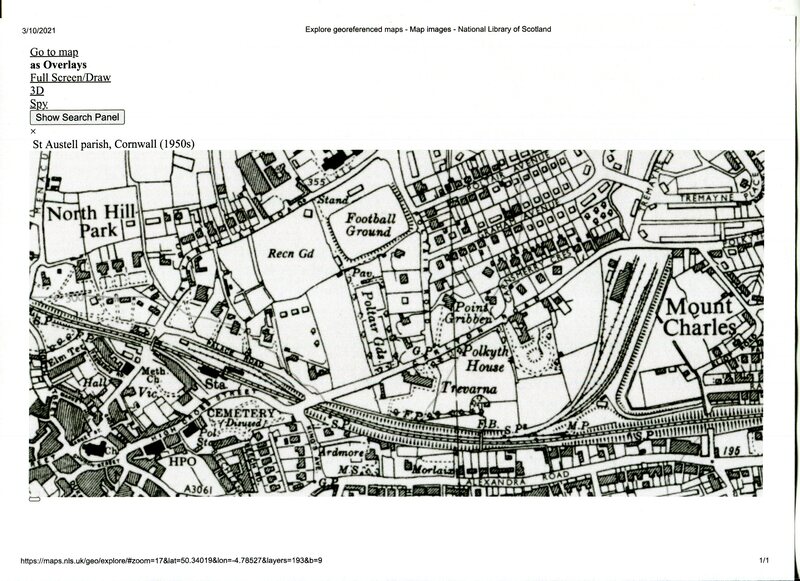

St Austell Goods Station located at Mount Charles opened in 1931 to ease congestion from the Goods Station situated in the Station Yard in St Austell. The Goods Station then became the Western National Bus Garage for many years until the 1970s when it relocated to Eliot Road, St Austell situated below the 1931 Goods Depot which ceased to be operational as the local pick up freight services ceased. Re organisation of the bus services also saw the closure of Eliot Road Bus Garage, St Austell with buses now stabled at a number of outlying locations. The last piece of line which later became a long siding from St Austell is due to be lifted, leaving only the crossover in St Austell Station used for the reversal of trains when the mainline is closed for engineering work.

A map courtesy of the National Museum of Scotland - non commercial use. Shows the relationship between St Austell Station and the goods yard which is about a quarter of a mile down grade for the station. There were several sidings in the goods yard which included a run round loop and some covered accommodation.

Entry and exit from the goods line were controlled by a ground frame located at the east end of the up platform at St Austell station. This line at one time formed an up and down goods loop with points leading out at the east end onto the up main there was also a cross over to bring down traffic into the loop.

_________________________________________________________________________________________________________________________________________________________________________________________

Now we look at a selection taken near and in the Goods Yard at St Austell

Leaving this location we head down the footpath to Alexandra Road passing the Capitol Bingo Hall on route

760627a A very rare event - a passenger train charted by the Branch Line Society was planned to run right into the goods yard at St Austell. However this tour was unable to access any further owing to tight clearances between the train and a van thoughtlessly parked close to the line.. Copyright Roger Winnen

During engineering work on the main line east of St Austell sometimes trains working at St Austell to Penzance shuttle reversed here and used the goods line as a refuge.

Mike Roach took this shot at St Austell on the 16th June 1981. 50042 Triumph now preserved at Bodmin sets off with a down train past the recently lifted down siding. In the background the engineers coaches remain. One wonders what the road coaches were there for, no doubt a bus replacement service. Copyright Mike Roach

The axe falls the removal of the line to the Goods Yard - Julian Stephens

Many thanks to Julian Stephens for these views from his collection.

Item 2105 Trewoon

gets a new bridge.

gets a new bridge.

Notes by Andrew Keast- Firstly from up the line from the site

Then various photos as things progressed. Work started at 18:00. The plan was to remove the bridge in sections. These were to be loaded onto a flatbed on the Burngulllow side of the bridge.

Large gas flame cutters were used to take out various struts/bolts. There were 3 working together.

As they progressed, the crane was brought in to take the weight.

Eventually at 21:15 the first section from the up line side was taken out.

I have been told that the bridge was completely removed by 02:00

Many thanks for your notes Andrew

Then various photos as things progressed. Work started at 18:00. The plan was to remove the bridge in sections. These were to be loaded onto a flatbed on the Burngulllow side of the bridge.

Large gas flame cutters were used to take out various struts/bolts. There were 3 working together.

As they progressed, the crane was brought in to take the weight.

Eventually at 21:15 the first section from the up line side was taken out.

I have been told that the bridge was completely removed by 02:00

Many thanks for your notes Andrew

The first section of the bridge on the move.

4th March 2021

Burngullow 4th March 2021.

East of Burngullow

Andrew Keast moves to Par to observe activities on the 4th March 2021

The new bridge and in service.

Congratulations to Network Rail and many thanks to all.

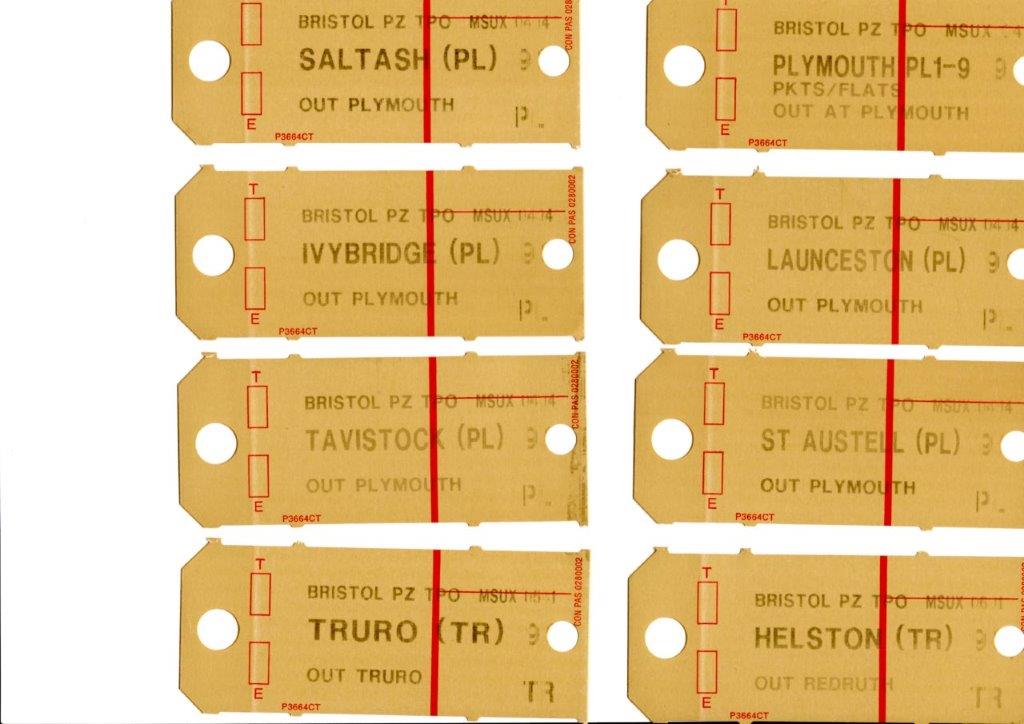

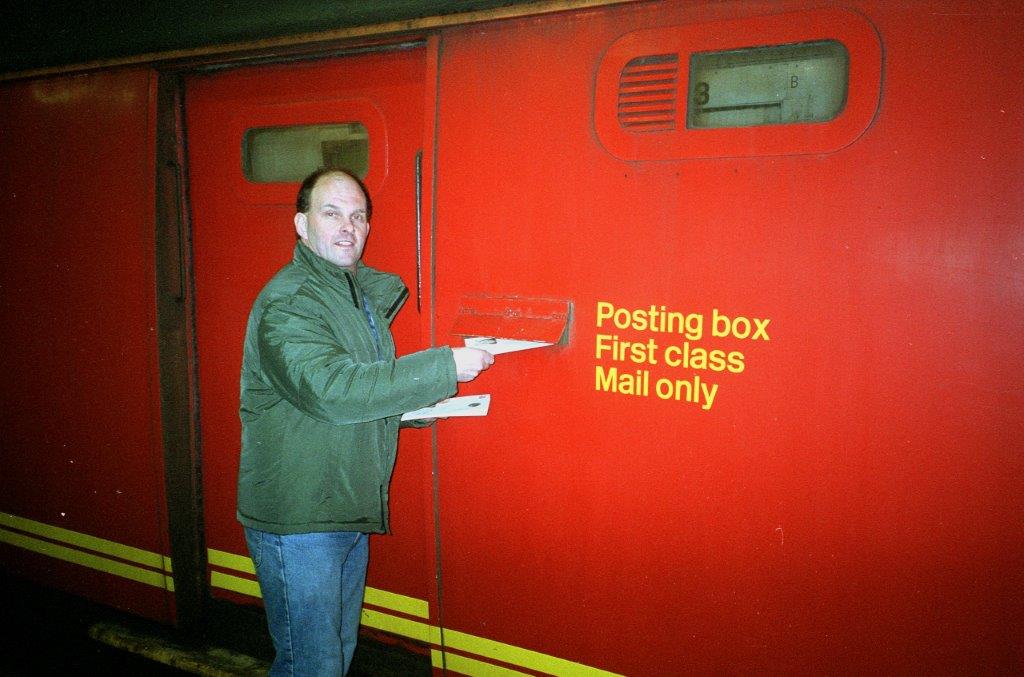

Item 2104

Remember the Royal Mail trains. Paul Barlow

Remember the Royal Mail trains. Paul Barlow

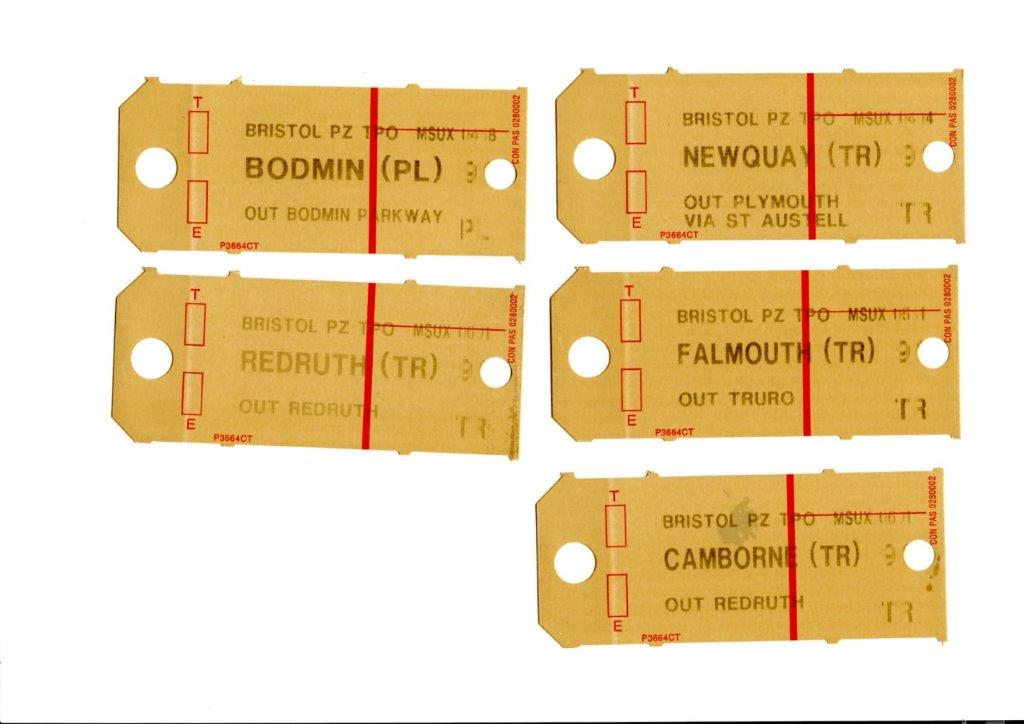

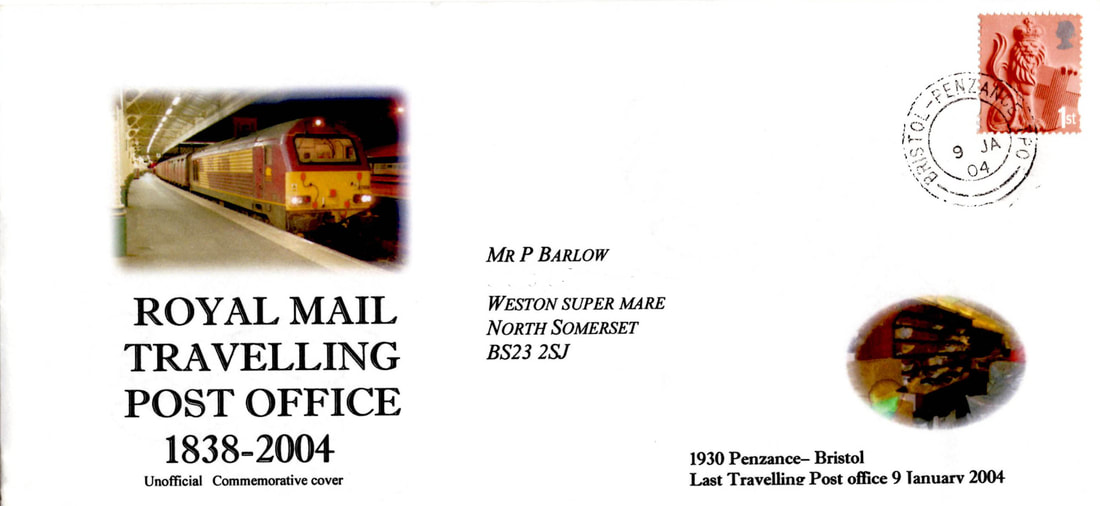

Continuing the Postal train theme.

A few shots from 9 January 2004 of the last Traveling post office (TPO) trains at Exeter St Davids. Post was sorted on the move on these trains.

I was lucky enough to be able to board the Penzance to Bristol service and see the postmen at work, which included hand franking mail.

Post boxes were also featured on the side of the coaches where you could post urgent letters, which I often did!

Another part of our railway heritage passed into history. I believe TPO's in some form had been running since 1838.

I have also included scans of the Mail bag label's which were given to me that night and a Commemorative Cover I made and posted on the Penzance to Bristol that night.

Hope you are well

All the best, Paul Barlow

A few shots from 9 January 2004 of the last Traveling post office (TPO) trains at Exeter St Davids. Post was sorted on the move on these trains.

I was lucky enough to be able to board the Penzance to Bristol service and see the postmen at work, which included hand franking mail.

Post boxes were also featured on the side of the coaches where you could post urgent letters, which I often did!

Another part of our railway heritage passed into history. I believe TPO's in some form had been running since 1838.

I have also included scans of the Mail bag label's which were given to me that night and a Commemorative Cover I made and posted on the Penzance to Bristol that night.

Hope you are well

All the best, Paul Barlow

The very last Royal mail Trains. Paul Barlow.

Many thanks to you Paul.

Item 2103

Relaying the

St Ives branch

Mid to late '50's.

Relaying the

St Ives branch

Mid to late '50's.

Before we look at what reports we have of the most recent relaying work on the St Ives branch which was completed with the branch re-opening to passenger traffic on Monday 8th of February 2021. I received on15th January the following most interesting article on memories from Laurence Hansford of how it was done in the 'Good Old Days'.

Happy New Year, Keith,

Well, there’s a thing! I never imagined that they would be re-laying a mile and a half with long welded track! Apart from the last three years (when they replaced the track at Lelant, fiddled with the platforms at St Erth and installed a new bridge at Griggs Quay) maintenance of the branch has been, shall we say, skimped (others might say woefully neglected). Most of the track from the footbridge just over Carbis Bay Viaduct up to about where the Distant Signal is now is concrete sleeepered and I remember that being done in the mid to late -50s, more than 60 years ago. Funnily enough, the next section of track towards St Ives, with wooden sleepers, is actually newer and I watched that work being done about 1960.

All the work was done on Sundays just out of season when the weather was still OK and there were no trains. The entire process was done manually by a team of about 2 dozen men, their only powered machine being the steam engine which propelled their train which consisted of a mess coach, a couple of bogie bolster waggons loaded with rails, some drop-sided trucks loaded with sleepers, a couple of empty trucks and some hoppers full of new ballast. The mess coach was a an ancient 3rd/brake with some compartments removed, leaving enough seats for the gang, the remainder of the space being for their tools and gear but with a coke stove for a brew. My recollection is that this was arranged to be next to the loco with the steam heating connected-up so they had somewhere warm to take their breaks!

The sleepers were all brand new treated timber but with reclaimed chairs and the 60 ft bull-head rails were second-hand but little worn, having been recovered (so I was told) from fast main line service where they were being replaced by flat bottom track. I believe the new ballast came from a quarry which used to exist alongside the main line at Menheniot. The gang worked pretty hard and would very methodically re-lay something like 5 lengths in a day but to do this they had to work as a team.

The procedure, at least as I recall it, was as follows: The train would slowly draw forward and a team of 4-5 men on the bogie bolster would use crowbars to lever rails to the edge to be deposited in pairs alongside each length of track to be renewed, all on the same side. Next, the train would re-trace its steps and the men on it would transfer their attention to the trucks with the new sleepers, where the latter would be manoeuvred to the edge. The men on the ground would then lift them off and stack them neatly alongside the new rails The train would then retire clear of the work area.

The team then transferred their attention to the track, concentrating on and completing one length at a time. The first things to be done would be to knock out all the keys and remove the fishplates. This allowed both rails to be lifted out and deposited on the other side of the track from the new materials. The men then set-to with shovels on the old ballast, clearing it out from between the sleepers and throwing it out just beyond the old rails, and being careful to scrape it out to the level of the bottom of the old sleepers but no further. Then, the old sleepers would be lifted off and dumped on the old ballast ready to be collected later. Lastly the now flattish ballast bed would be checked and any irregularities corrected to the satisfaction of the ganger, foreman or inspector or whatever he was called (I am not sure which but, remembering this was West Cornwall 60 years ago, I rather think it would have been “Cap’n” or “Skip’”!).

Relaying could then commence, starting with the new sleepers which were carried into position on the cleared track-bed being very careful to ensure that the chairs were all in line. The team then got to together to carry the new rails and place them in their new homes after which all the fishplates were replaced and the bolts tightened. Before driving the keys back into the chairs, considerable attention was paid to make sure that all the sleepers were evenly spaced and not skewed and that the rails were straight. Once the keys had all been driven home the last thing to do was to ram the ballast under the sleepers (whilst access was still easy) to make sure they were all properly supported.

Having thus made the track safe enough so that their train could later pass over depositing new ballast, the team then moved on to the next length to be done and repeated the whole performance as above. Once the requisite number of lengths had been completed (I seem to think they managed 5 in a day) the Cap’n would spend some time checking the alignment of the new track directing adjustments, as required. When finally satisfied the train proceeded very slowly and the controls on the hopper wagons would be operated to drop the right amount to fill the gaps between the sleepers and once the train had passed the men set to with their shovels to put the finishing touches to the new track.

One might imagine that, at this point the men could gather up their gear, jump back on the train and clear off home; unfortunately in those days, this was not the case – they had to clear up site first! This was just as organised as the relaying itself. First to be loaded back onto the train were the old sleepers. These were loaded back on the wagons which had brought the new ones, taking up roughly the same space, except for the few which didn’t make it in one piece. Then it was the turn of the rails and, in broad terms, they were also put back where the new ones had been, except that in this case the procedure formed a spectacle in its own right! Bearing in mind that standard 60 ft Bull-Head rail weighs 97½lb per Yard, making each rail weigh the best part of a ton, lifting them off the ground to above shoulder height was not a job for the faint-hearted. Even with 24 men the only way to make it reasonably easy was with a well-rehearsed routine with the help of the railway equivalent of a sea shanty. In unison, the men would sing out something like 1,2,3-up-1,2,3-up-1,2,3-up-1,2,3-up… and the rail would magically rise from the ground until deposited on the edge of the bogey bolster from where it would be crow-barred home. The last job was then to shovel all the old ballast back into the empty waggons but my recollection is that, to save time, a lot of it was piled on top of the old sleepers. (It meant that they could work along the length of 5 or 6 wagons instead of just a couple.)

After a quick tidy up and the loading of all their tools, off they went leaving the track ready for the commencement of normal running on Monday morning. Although at this stage the new track appeared perfect, I imagine that in the next week or two the St Ives Ganger and his assistant (they lived in the brick building on the other side of the track from the Engine Shed) would make final adjustments re-packing the track and getting the alignment perfect as passing trains shook all the individual lumps of gravel into a better fit with one another. All I can tell you is that, although I very rarely saw them, they kept the whole line in petty much immaculate condition with all straight track (not that there is much of it apart from over the Lelant Towans) dead straight and all curves nice and smooth.

I note that they say it will take 5 weeks to re-lay 1½ miles; this is interesting. There are 88 standard 60 ft lengths per mile and hence 1½ miles would be equivalent to 132 lengths. If the men are working a 6 day week, 5 weeks would contain 30 working days. That means that they will be re-laying the equivalent of 132/30 = 4.4 standard lengths per day. The bit I find interesting is that 60 years later, with all their up-to-date highly mechanised machinery they can’t achieve what a couple of dozen men were able to do with their bare hands. And, by “bare hands” I mean just that, no gloves or any other sort of PPE except that I think they were issued with oil-skins so that they could continued to work in bad weather. They just wore their old clothes and I think even provided their own hob-nailed boots (no steel toe caps as far as I know). In fact, I don’t remember seeing any railway workers wearing gloves, not even firemen shovelling coal! As for all-weather Hi-Viz jackets and helmets with shatter proof visors… dream on.

The photos of all the new material dumped around Carbis Bay Station do raise an intriguing question: How did it all get there? As for the rails, the answer is pretty self-evident, bearing in mind the recent rail delivery trains with the enigmatic destination of St Erth but the pallets of steel sleepers and bags of ballast are a different matter. Normally, on branch lines, it seems these, as well as the machines themselves are delivered by road to convenient points along the line but the St Ives line is a bit different: Most of it is balanced along the cliff edge where it is not possible for a road to be anywhere near and, between Lelant Station and St Ives Station there are simply no roads near the line capable of taking HGVs and the only “road” that does isn’t close to the line where the two are at roughly level. Even at Carbis Bay Station, where it probably would be possible to get an HGV into the Station car park there is certainly no track-side road access. So, how are they doing it? By rail, or is that too obvious.

Laurence Hansford.

Well, there’s a thing! I never imagined that they would be re-laying a mile and a half with long welded track! Apart from the last three years (when they replaced the track at Lelant, fiddled with the platforms at St Erth and installed a new bridge at Griggs Quay) maintenance of the branch has been, shall we say, skimped (others might say woefully neglected). Most of the track from the footbridge just over Carbis Bay Viaduct up to about where the Distant Signal is now is concrete sleeepered and I remember that being done in the mid to late -50s, more than 60 years ago. Funnily enough, the next section of track towards St Ives, with wooden sleepers, is actually newer and I watched that work being done about 1960.

All the work was done on Sundays just out of season when the weather was still OK and there were no trains. The entire process was done manually by a team of about 2 dozen men, their only powered machine being the steam engine which propelled their train which consisted of a mess coach, a couple of bogie bolster waggons loaded with rails, some drop-sided trucks loaded with sleepers, a couple of empty trucks and some hoppers full of new ballast. The mess coach was a an ancient 3rd/brake with some compartments removed, leaving enough seats for the gang, the remainder of the space being for their tools and gear but with a coke stove for a brew. My recollection is that this was arranged to be next to the loco with the steam heating connected-up so they had somewhere warm to take their breaks!

The sleepers were all brand new treated timber but with reclaimed chairs and the 60 ft bull-head rails were second-hand but little worn, having been recovered (so I was told) from fast main line service where they were being replaced by flat bottom track. I believe the new ballast came from a quarry which used to exist alongside the main line at Menheniot. The gang worked pretty hard and would very methodically re-lay something like 5 lengths in a day but to do this they had to work as a team.

The procedure, at least as I recall it, was as follows: The train would slowly draw forward and a team of 4-5 men on the bogie bolster would use crowbars to lever rails to the edge to be deposited in pairs alongside each length of track to be renewed, all on the same side. Next, the train would re-trace its steps and the men on it would transfer their attention to the trucks with the new sleepers, where the latter would be manoeuvred to the edge. The men on the ground would then lift them off and stack them neatly alongside the new rails The train would then retire clear of the work area.

The team then transferred their attention to the track, concentrating on and completing one length at a time. The first things to be done would be to knock out all the keys and remove the fishplates. This allowed both rails to be lifted out and deposited on the other side of the track from the new materials. The men then set-to with shovels on the old ballast, clearing it out from between the sleepers and throwing it out just beyond the old rails, and being careful to scrape it out to the level of the bottom of the old sleepers but no further. Then, the old sleepers would be lifted off and dumped on the old ballast ready to be collected later. Lastly the now flattish ballast bed would be checked and any irregularities corrected to the satisfaction of the ganger, foreman or inspector or whatever he was called (I am not sure which but, remembering this was West Cornwall 60 years ago, I rather think it would have been “Cap’n” or “Skip’”!).

Relaying could then commence, starting with the new sleepers which were carried into position on the cleared track-bed being very careful to ensure that the chairs were all in line. The team then got to together to carry the new rails and place them in their new homes after which all the fishplates were replaced and the bolts tightened. Before driving the keys back into the chairs, considerable attention was paid to make sure that all the sleepers were evenly spaced and not skewed and that the rails were straight. Once the keys had all been driven home the last thing to do was to ram the ballast under the sleepers (whilst access was still easy) to make sure they were all properly supported.

Having thus made the track safe enough so that their train could later pass over depositing new ballast, the team then moved on to the next length to be done and repeated the whole performance as above. Once the requisite number of lengths had been completed (I seem to think they managed 5 in a day) the Cap’n would spend some time checking the alignment of the new track directing adjustments, as required. When finally satisfied the train proceeded very slowly and the controls on the hopper wagons would be operated to drop the right amount to fill the gaps between the sleepers and once the train had passed the men set to with their shovels to put the finishing touches to the new track.

One might imagine that, at this point the men could gather up their gear, jump back on the train and clear off home; unfortunately in those days, this was not the case – they had to clear up site first! This was just as organised as the relaying itself. First to be loaded back onto the train were the old sleepers. These were loaded back on the wagons which had brought the new ones, taking up roughly the same space, except for the few which didn’t make it in one piece. Then it was the turn of the rails and, in broad terms, they were also put back where the new ones had been, except that in this case the procedure formed a spectacle in its own right! Bearing in mind that standard 60 ft Bull-Head rail weighs 97½lb per Yard, making each rail weigh the best part of a ton, lifting them off the ground to above shoulder height was not a job for the faint-hearted. Even with 24 men the only way to make it reasonably easy was with a well-rehearsed routine with the help of the railway equivalent of a sea shanty. In unison, the men would sing out something like 1,2,3-up-1,2,3-up-1,2,3-up-1,2,3-up… and the rail would magically rise from the ground until deposited on the edge of the bogey bolster from where it would be crow-barred home. The last job was then to shovel all the old ballast back into the empty waggons but my recollection is that, to save time, a lot of it was piled on top of the old sleepers. (It meant that they could work along the length of 5 or 6 wagons instead of just a couple.)

After a quick tidy up and the loading of all their tools, off they went leaving the track ready for the commencement of normal running on Monday morning. Although at this stage the new track appeared perfect, I imagine that in the next week or two the St Ives Ganger and his assistant (they lived in the brick building on the other side of the track from the Engine Shed) would make final adjustments re-packing the track and getting the alignment perfect as passing trains shook all the individual lumps of gravel into a better fit with one another. All I can tell you is that, although I very rarely saw them, they kept the whole line in petty much immaculate condition with all straight track (not that there is much of it apart from over the Lelant Towans) dead straight and all curves nice and smooth.

I note that they say it will take 5 weeks to re-lay 1½ miles; this is interesting. There are 88 standard 60 ft lengths per mile and hence 1½ miles would be equivalent to 132 lengths. If the men are working a 6 day week, 5 weeks would contain 30 working days. That means that they will be re-laying the equivalent of 132/30 = 4.4 standard lengths per day. The bit I find interesting is that 60 years later, with all their up-to-date highly mechanised machinery they can’t achieve what a couple of dozen men were able to do with their bare hands. And, by “bare hands” I mean just that, no gloves or any other sort of PPE except that I think they were issued with oil-skins so that they could continued to work in bad weather. They just wore their old clothes and I think even provided their own hob-nailed boots (no steel toe caps as far as I know). In fact, I don’t remember seeing any railway workers wearing gloves, not even firemen shovelling coal! As for all-weather Hi-Viz jackets and helmets with shatter proof visors… dream on.

The photos of all the new material dumped around Carbis Bay Station do raise an intriguing question: How did it all get there? As for the rails, the answer is pretty self-evident, bearing in mind the recent rail delivery trains with the enigmatic destination of St Erth but the pallets of steel sleepers and bags of ballast are a different matter. Normally, on branch lines, it seems these, as well as the machines themselves are delivered by road to convenient points along the line but the St Ives line is a bit different: Most of it is balanced along the cliff edge where it is not possible for a road to be anywhere near and, between Lelant Station and St Ives Station there are simply no roads near the line capable of taking HGVs and the only “road” that does isn’t close to the line where the two are at roughly level. Even at Carbis Bay Station, where it probably would be possible to get an HGV into the Station car park there is certainly no track-side road access. So, how are they doing it? By rail, or is that too obvious.

Laurence Hansford.

Because of the Lockdown which commenced in January there was little feedback or pictures on this fascinating engineering operation which took place on our 'patch' which we felt barred from observing

It was felt wrong to encourage the general public go out and photograph the operation in view of the 'Stay at Home advice. However', it was thought that it would be excusable/permissible if photographs were taken by members of staff on duty or members of the public on ' legitimate exercise'.

It was felt wrong to encourage the general public go out and photograph the operation in view of the 'Stay at Home advice. However', it was thought that it would be excusable/permissible if photographs were taken by members of staff on duty or members of the public on ' legitimate exercise'.

Many thanks Laurence for your most interesting article on how things were done in the past.

Now to a report on the latest relay in 2021- a major operation.

Report by Mick House

Many thanks to Mick for the following article on the renewal work

Report by Mick House

Many thanks to Mick for the following article on the renewal work

Track renewal on the St Ives Branch.

Track renewal on the St Ives branch started off, prior to the 5th Jan start date with materials and plant being delivered to a compound adjacent to St Erth station and materials being delivered trackside at various locations including St Ives and Carbis Bay stations, also including long welded rail at the location of the renewal.

The track on the St Ives branch is Bullhead rail, chaired with wooden keys on concrete or wooden sleepers (Photo 1) and is being replaced by long welded flat bottomed rail on a rubber pad clipped directly on to steel sleepers.

All of the old track that is being lifted from the buffer stops at St Ives to the finishing point, is being chopped into around approximately 12 foot sections and transported on two rail trailers one each end of a Komatsu PW160-8 Megarailer 360 machine (Photo 2) machine No. 1030), to St Erth for onward disposal possibly by road or rail?.

Track renewal on the St Ives branch started off, prior to the 5th Jan start date with materials and plant being delivered to a compound adjacent to St Erth station and materials being delivered trackside at various locations including St Ives and Carbis Bay stations, also including long welded rail at the location of the renewal.

The track on the St Ives branch is Bullhead rail, chaired with wooden keys on concrete or wooden sleepers (Photo 1) and is being replaced by long welded flat bottomed rail on a rubber pad clipped directly on to steel sleepers.

All of the old track that is being lifted from the buffer stops at St Ives to the finishing point, is being chopped into around approximately 12 foot sections and transported on two rail trailers one each end of a Komatsu PW160-8 Megarailer 360 machine (Photo 2) machine No. 1030), to St Erth for onward disposal possibly by road or rail?.

Condition of the old track that has been removed.

Looking at the track sections stock piled at St Erth, you can see that they look as though they have been bitten or hack off (Photos 3 & 4) and in fact they have been sheared off, with the use of a Track Shear machine (Photo 5 & 6 not the one used on the site as I did not get a good enough shot). The track shear with its two hydraulic cylinders each exerting 350 Bar (over 5000 pounds per square inch) of pressure can cut the rail like you or me snapping a twig.

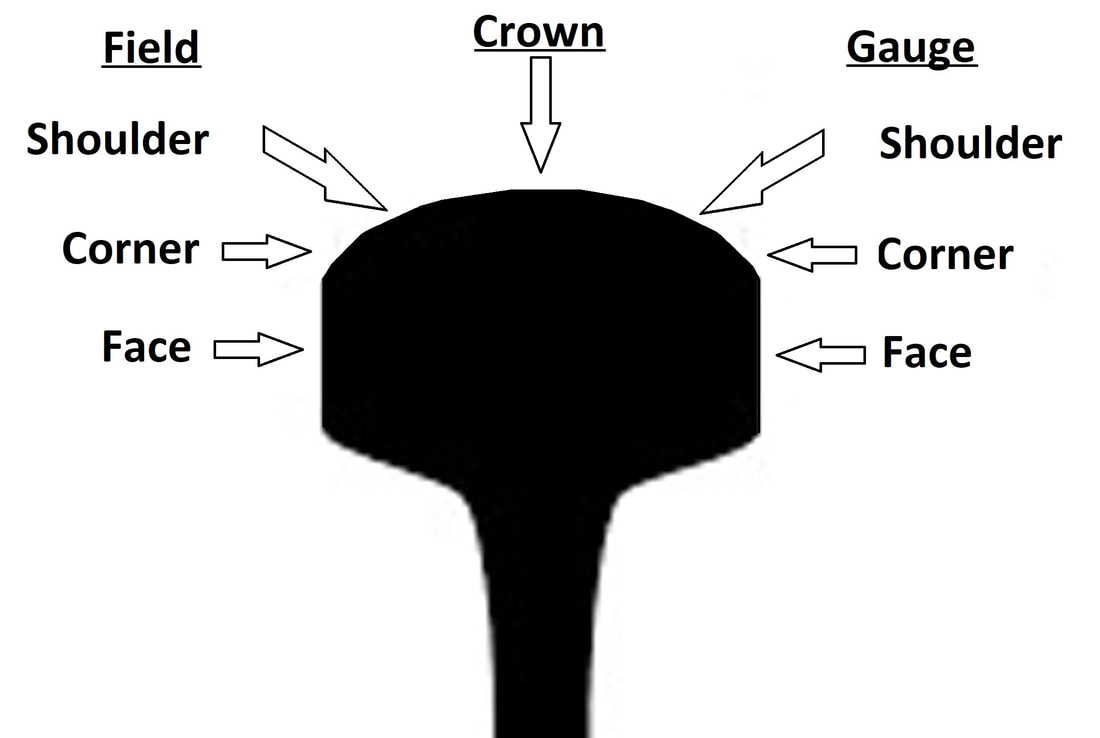

The amount of wear sustained on the track over years can be seen by looking at the profile of the rails (Photos 7, 8 & 9), the top of the rail or rail head may have multiple types of wear, for example the rail I have photographed has Vertical Wear, Gauge Wear and Plastic Flow. The rail head is made up of three main parts (Photo 10), the Crown, Gauge and Field. Crown: is the top of the rail. Gauge: is the inside edge of the rail with three areas: Shoulder, Corner and Face. Field: is the outside edge of the rail with three areas: Shoulder, Corner and Face.

Gauge Wear can be on the Shoulder, Corner or Face or a combination of the three and predominantly will occur on curved track, the Crown can also be affected (photo 11).

Field Wear is not as common but dose effect the Shoulder and Corner and to a lesser extent the face this is usually in conjunction with Crown wear (Photo 12).

Crown Wear also Vertical Wear to the top of the rail is probably the most common as the wheels are in contact with the top of the rail most of the time.

All of this amounts to a worn-out profile, rendering the rail potently dangerous so needs to be replaced. There is a lot more I could say on the subject rails in a lot more detail, but I am sure that this is enough at this time (Photo 12)

Looking at the track sections stock piled at St Erth, you can see that they look as though they have been bitten or hack off (Photos 3 & 4) and in fact they have been sheared off, with the use of a Track Shear machine (Photo 5 & 6 not the one used on the site as I did not get a good enough shot). The track shear with its two hydraulic cylinders each exerting 350 Bar (over 5000 pounds per square inch) of pressure can cut the rail like you or me snapping a twig.

The amount of wear sustained on the track over years can be seen by looking at the profile of the rails (Photos 7, 8 & 9), the top of the rail or rail head may have multiple types of wear, for example the rail I have photographed has Vertical Wear, Gauge Wear and Plastic Flow. The rail head is made up of three main parts (Photo 10), the Crown, Gauge and Field. Crown: is the top of the rail. Gauge: is the inside edge of the rail with three areas: Shoulder, Corner and Face. Field: is the outside edge of the rail with three areas: Shoulder, Corner and Face.

Gauge Wear can be on the Shoulder, Corner or Face or a combination of the three and predominantly will occur on curved track, the Crown can also be affected (photo 11).

Field Wear is not as common but dose effect the Shoulder and Corner and to a lesser extent the face this is usually in conjunction with Crown wear (Photo 12).

Crown Wear also Vertical Wear to the top of the rail is probably the most common as the wheels are in contact with the top of the rail most of the time.

All of this amounts to a worn-out profile, rendering the rail potently dangerous so needs to be replaced. There is a lot more I could say on the subject rails in a lot more detail, but I am sure that this is enough at this time (Photo 12)

Ballast Trains

Two of the trains that took ballast to the Branch

Top 66 167 & tailed 66 020 with ten Autoballasters, departed Westbury 11.25 Tuesday 12th Jan arriving at St Erth 20.15 the same day, it departed St Erth 08.02 Wednesday 13th Jan, I photographed it at Wheal Busy Crossing as it returned to Westbury, and it arrived 13.02 the same day (Photos 12 & 13).

Top 66 059 & tailed 66 107 with ten Autoballasters, departed Westbury 11.59 Wednesday 13th Jan arriving at St Erth 20.09 the same day, it departed St Erth 07.55 Thursday 14th January. I photographed it at Wheal Busy Crossing as it returned to Westbury, and it arrived 13.08 the same day (Photos 14 & 15).

Two of the trains that took ballast to the Branch

Top 66 167 & tailed 66 020 with ten Autoballasters, departed Westbury 11.25 Tuesday 12th Jan arriving at St Erth 20.15 the same day, it departed St Erth 08.02 Wednesday 13th Jan, I photographed it at Wheal Busy Crossing as it returned to Westbury, and it arrived 13.02 the same day (Photos 12 & 13).

Top 66 059 & tailed 66 107 with ten Autoballasters, departed Westbury 11.59 Wednesday 13th Jan arriving at St Erth 20.09 the same day, it departed St Erth 07.55 Thursday 14th January. I photographed it at Wheal Busy Crossing as it returned to Westbury, and it arrived 13.08 the same day (Photos 14 & 15).

Very sincere thanks to Mick House who took this collection of photographs and put the article together.

Peter Radford (Manchester) sent some questions concerning the renewal work on the St Ives branch which Mick House has kindly undertaken to answer.

Questions and Answers

ST.IVES BRANCH TRACK RENEWAL 2021

Question :- I am sure that many members would be interested in the operational plan to carry out this work, does the society have contact with Network Rail, do they have a photographic record of their work that they would be willing to share? They will probably have a photographic record, but nothing as yet.

I am not an engineer so have to presume things like – was the track cut into small sections to allow removal by road/rail vehicles, did they then take the sections to St Erth to transfer to an engineering train? Was this repeated with the old ballast? Did the work commence at St Ives?

I believe that that the new” base” ballast, sleepers and C/W rail were delivered when the mainline closure took place in December??

Answer :- All of the old track that is being lifted from the buffer stops at St Ives (start Point) to the finishing point and is being chopped into around approximately 12 foot sections and transported on two rail trailers one each end of a Komatsu PW160-8 Megarailer 360 machine, to St Erth for onward disposal possibly by road or rail?. An amount of ballast was stock piled in one ton bags along the branch including Carbis bay and St Ives. Uncertain were the old ballast has gone but I suspect it was put to the side of the track!

Question :- Is Nut Grove “crossing” the start of the new track and will there be an expansion joint here?

On the 14th Jan we had our first pictures of the auto ballast train at St Erth and in Carbis Bay station awaiting to proceed to St Ives, but I do not understand how this train can safely traverse the new track which is basically only sitting on top of a base ballast ?? (Please excuse my naivety!)

Answer :- A temporary connection of old to new rail is made so that trains can traverse the line. You have no problem with trains travelling over un-ballasted track. At the time of righting this, seven autoballaster trains and two Tampers have been up the branch, starting on the evening of 11th January 2021.

When did the tamping commence and when will the test train make a visit?

Answer :- Tamping started after the sixth ballast train had finished on the 17th January 2021. Test trains will start running up the branch after all of the work is complete.

Is the work on schedule? :

-

We all now know that the branch relaying was a complete success with the work completed on time for the return of normal services on the 9th February 2021. Congratulations to Network Rail.

Question by Peter Radford (Manchester).

Answers by Mick House.

The following snippets received from Craig Munday - Many thanks Craig.

I've been trying to grab a press release for you regarding the St Ives 2km track renewals, I have found some snippets for you:

Work will start in the new year on upgrading the track between Carbis Bay and St Ives in a £3m project by Network Rail.

In what has been described as the biggest track investment in Cornwall since the 1950s, Network Rail will be carrying out work over a 5 week period between Sunday the 3rd of January and Monday the 8th of February 2021

Around 1.5 miles of new track will be laid along with 3,600 new railway sleepers and over 400 tonnes of ballast.

Lee Hildreth, Network Rail’s project manager, said: “This is a huge piece of work, but it will make a real difference as it will reduce delays and improve reliability for passengers in Cornwall.”

“It is the biggest track upgrade for generations, and it has been planned so it can be done as safely and as quickly as possible.”

“However, buses will replace trains while the work is ongoing, so we urge passengers to check before they travel and thanks them in advance for their patience.”

Mark Chorley, GWR Regional Station Manager, West, said: “We have been working hard to make sure that people can be confident to travel safely, and that includes running as many replacement buses as we can to make extra room, as well as enhanced cleaning and social distancing measures.”

“This work is important to ensure we can continue to maintain and improve reliability on this very popular and scenic branch line, and we thank customers for their patience in advance.”

It doesn't answer the many questions from Mr Radford, so I suggest he writes direct to NR.

I've been trying to grab a press release for you regarding the St Ives 2km track renewals, I have found some snippets for you:

Work will start in the new year on upgrading the track between Carbis Bay and St Ives in a £3m project by Network Rail.

In what has been described as the biggest track investment in Cornwall since the 1950s, Network Rail will be carrying out work over a 5 week period between Sunday the 3rd of January and Monday the 8th of February 2021

Around 1.5 miles of new track will be laid along with 3,600 new railway sleepers and over 400 tonnes of ballast.

Lee Hildreth, Network Rail’s project manager, said: “This is a huge piece of work, but it will make a real difference as it will reduce delays and improve reliability for passengers in Cornwall.”

“It is the biggest track upgrade for generations, and it has been planned so it can be done as safely and as quickly as possible.”

“However, buses will replace trains while the work is ongoing, so we urge passengers to check before they travel and thanks them in advance for their patience.”

Mark Chorley, GWR Regional Station Manager, West, said: “We have been working hard to make sure that people can be confident to travel safely, and that includes running as many replacement buses as we can to make extra room, as well as enhanced cleaning and social distancing measures.”

“This work is important to ensure we can continue to maintain and improve reliability on this very popular and scenic branch line, and we thank customers for their patience in advance.”

It doesn't answer the many questions from Mr Radford, so I suggest he writes direct to NR.

Received on the 2nd February.

An EXTREMELY INTERESTING collection of pictures of the

ST. IVES RELAY OPERATION FROM PAUL BARRIBALL

With very many thanks to PAUL for sending the following pictures which we as 'JOE PUBLIC' could never get.

An EXTREMELY INTERESTING collection of pictures of the

ST. IVES RELAY OPERATION FROM PAUL BARRIBALL

With very many thanks to PAUL for sending the following pictures which we as 'JOE PUBLIC' could never get.

Pictures in order working away from the St Ives terminus

Many thanks to Paul Barriball and also to Graham Mann who contacted him on our behalf.

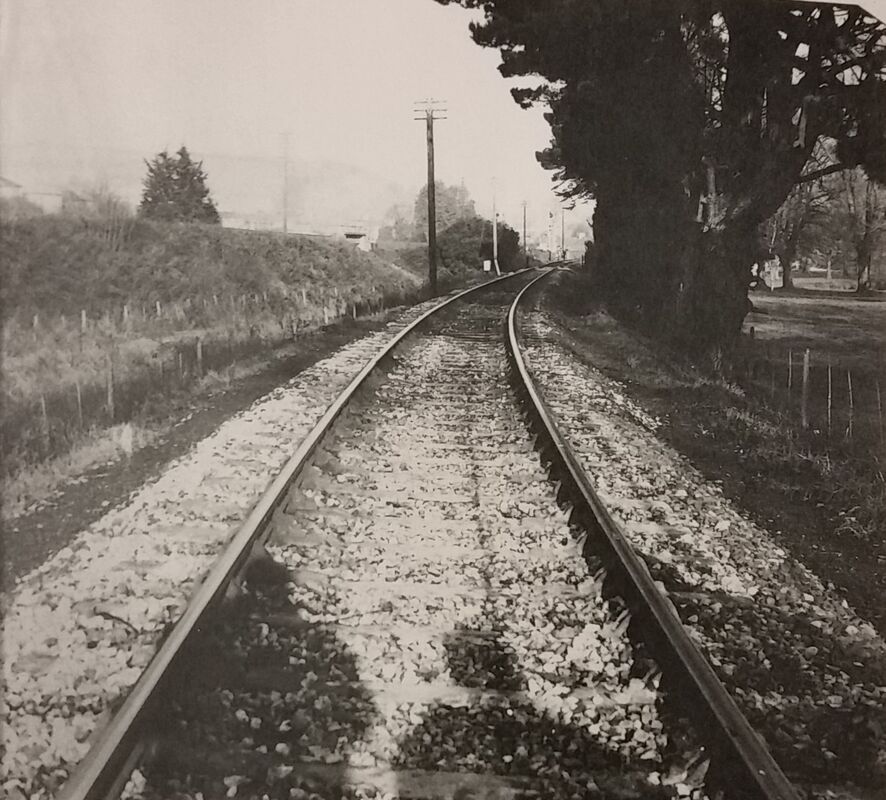

Item 2102 Reopening the branch to Okehampton - A collection of pictures

Item 2102

Good news. Today, 18th March 2021 is the official launch of work on the Okehampton branch. The line now has a website:- https://dartmoorline.com/ Somewhat ironic that some 29000 tons of ballast will be moved to the line when at the end of the line is mothballed Meldon Quarry. Dave

Reopening the branch to Okehampton - A collection of pictures

Good news. Today, 18th March 2021 is the official launch of work on the Okehampton branch. The line now has a website:- https://dartmoorline.com/ Somewhat ironic that some 29000 tons of ballast will be moved to the line when at the end of the line is mothballed Meldon Quarry. Dave

Reopening the branch to Okehampton - A collection of pictures

Class 70's to Okehampton

Colas Rail class 70's visited Okehampton with the first of many concrete sleeper trains for upgrading the line as part of the National Network, special dispensation has been given for class 70's by Network Rail and 70809 top and tailed with 70815 worked to Okehampton with 6C42 in the evening of 13th January where the sleepers were offloaded into Okehampton car park where Network Rail have set up a compound for working on the line. Looking back towards the station from the back of the train, note the bags of ballast to the right with the name of the new owners of the line.

Alan Peters

Colas Rail class 70's visited Okehampton with the first of many concrete sleeper trains for upgrading the line as part of the National Network, special dispensation has been given for class 70's by Network Rail and 70809 top and tailed with 70815 worked to Okehampton with 6C42 in the evening of 13th January where the sleepers were offloaded into Okehampton car park where Network Rail have set up a compound for working on the line. Looking back towards the station from the back of the train, note the bags of ballast to the right with the name of the new owners of the line.

Alan Peters

Class 70's to Okehampton

Colas Rail 70809 top and tailed with 70815 worked to Okehampton with 6C42 working back to Westbury on 14th January, 70815 is seen in the distance waiting to depart from Okehampton, this is the fixed distant signal for Okehampton, please note that all the pictures are taken under T3 conditions - Alan Peters