ENGINEERING PLANT DIARY

Compiled by Mick House.

The Plain Line Pattern Recognition Train (PLPR) at Penzance on 05.04.2024

Mick House

On Track Plant used in the 2024 re-signalling project

Mick House

Please also see our re-signalling section (click here) which features many photographs of these machines in action.

To view Micks record of the machinery used in this project, please expand one of the sections below.

To view Micks record of the machinery used in this project, please expand one of the sections below.

TRAILERS

Wheeled Excavators

TRACKED EXCAVATORS

Large Plant

Road/Rail Excavator the Komatsu PW170ES. By Mick House.

This article was first published in our CRS magazine on the 15th June 2011.

The Komatsu PW170ES is a road/rail excavator a smaller bit of plant, but just as important as its larger rail bound brothers. This machine number 444 (picture 01) is the Komat`su PW170ES owned by Quattro, it has a 3.92 litre, 91 KW, 121 horse power at 2200 RPM 4 cylinder, direct injection, turbo charged, intercooled Komatsu SAA4D102-E2 diesel engine (what a mouth full!). The engine powers a hydraulic pump incorporated in HydrauMind Komatsu’s unique hydraulic system. In the HydrauMind system, the load sensing valves and pressure compensated valves automatically handle all adjustments for individual work applications based on the pressure and lever stroke they sense. The machine has a 250-litre fuel and 135 litre hydraulic oil tanks.

It has fully automatic transmission with permanent 4-wheel drive and three travel modes: High mode 0 to 30.0 km/h, Medium mode 0 to 10.0 km/h and Low mode 0 to 3.5 km/h all in forward or reverse. It is 8.26 meters long (27.126 feet) and 2.5 meters wide (8.2 feet). When in travel mode, it has a maximum reach of just over 9 meters, can work to a depth of just over 5 meters and rotates a full 360 degrees.

These machines have rail guidance fitted to enable them to travel on the railway. They can travel at the same speeds as on the road but will be restricted to line speeds governed by Network Rail, for example on rail a maximum working speed of 2.41km/h (1.5MPH). Komat`su do not fit rail guidance wheels to their machines as standard, these are fitted by independent company’s like Quattro plant and Rexquote. This Quattro version is also fitted with a quick release mechanism and lifting hook (picture 02) to enable it to fit different attachments to it operating arm. Attachments with this machine on the day were a sleeper grab (picture 03), a ballast bucket (picture 04), a thimble which enables the rail to move through itself as the machine is lifting rail in to position (picture 05) and also a four wheeled rail trolley (picture 01) that it tows along. Other attachments that can be incorporated into these machines are ballast brushes, rail cutters, rotary cutters, tamping banks, flails, ploughs, steel sleeper grabs, profile buckets, rock breakers, grabs, lifting beams, access platforms, ripper teeth, augers, vibrating plates and many more. Around the time of its visit, the machine was engaged in the replacement of individual sleepers and ballast in the area.

As an up date to this article sister machine number 467 was in Truro yard on 18-04-2012 and it had been modified with disc brakes on the rail guidance wheels to allow it to tow greater loads on rail, (picture 06) shows a before modification shot and (picture 07) shows an after modification shot. It has also been fitted with extra ballast weight (picture 08) to enable it to lift heavier loads, this is the black rectangular box situated under the second step and stretching across the underside of the machine.

Words and Photos by Mick House.

The Komatsu PW170ES is a road/rail excavator a smaller bit of plant, but just as important as its larger rail bound brothers. This machine number 444 (picture 01) is the Komat`su PW170ES owned by Quattro, it has a 3.92 litre, 91 KW, 121 horse power at 2200 RPM 4 cylinder, direct injection, turbo charged, intercooled Komatsu SAA4D102-E2 diesel engine (what a mouth full!). The engine powers a hydraulic pump incorporated in HydrauMind Komatsu’s unique hydraulic system. In the HydrauMind system, the load sensing valves and pressure compensated valves automatically handle all adjustments for individual work applications based on the pressure and lever stroke they sense. The machine has a 250-litre fuel and 135 litre hydraulic oil tanks.

It has fully automatic transmission with permanent 4-wheel drive and three travel modes: High mode 0 to 30.0 km/h, Medium mode 0 to 10.0 km/h and Low mode 0 to 3.5 km/h all in forward or reverse. It is 8.26 meters long (27.126 feet) and 2.5 meters wide (8.2 feet). When in travel mode, it has a maximum reach of just over 9 meters, can work to a depth of just over 5 meters and rotates a full 360 degrees.

These machines have rail guidance fitted to enable them to travel on the railway. They can travel at the same speeds as on the road but will be restricted to line speeds governed by Network Rail, for example on rail a maximum working speed of 2.41km/h (1.5MPH). Komat`su do not fit rail guidance wheels to their machines as standard, these are fitted by independent company’s like Quattro plant and Rexquote. This Quattro version is also fitted with a quick release mechanism and lifting hook (picture 02) to enable it to fit different attachments to it operating arm. Attachments with this machine on the day were a sleeper grab (picture 03), a ballast bucket (picture 04), a thimble which enables the rail to move through itself as the machine is lifting rail in to position (picture 05) and also a four wheeled rail trolley (picture 01) that it tows along. Other attachments that can be incorporated into these machines are ballast brushes, rail cutters, rotary cutters, tamping banks, flails, ploughs, steel sleeper grabs, profile buckets, rock breakers, grabs, lifting beams, access platforms, ripper teeth, augers, vibrating plates and many more. Around the time of its visit, the machine was engaged in the replacement of individual sleepers and ballast in the area.

As an up date to this article sister machine number 467 was in Truro yard on 18-04-2012 and it had been modified with disc brakes on the rail guidance wheels to allow it to tow greater loads on rail, (picture 06) shows a before modification shot and (picture 07) shows an after modification shot. It has also been fitted with extra ballast weight (picture 08) to enable it to lift heavier loads, this is the black rectangular box situated under the second step and stretching across the underside of the machine.

Words and Photos by Mick House.

Network Rail Measurement Train Rolling Stock (part 4). By Mick House.

We see a number of Network Rail Measurement Trains visit our area over the years and predominantly the photos that have been taken are of the Locomotives that bring the trains down, but what of the rolling stock that is within the train! Most of the vehicles you see are ex passenger carrying coaches or vehicles that have been used for other railway duties. I have put together a selection of these vehicles as I feel they do not get enough recognition. Words & photos by Mick House.

Network Rail Measurement Train Rolling Stock (part 3). By Mick House.

We see a number of Network Rail Measurement Trains visit our area over the years and predominantly the photos that have been taken are of the Locomotives that bring the trains down, but what of the rolling stock that is within the train! Most of the vehicles you see are ex passenger carrying coaches or vehicles that have been used for other railway duties. I have put together a selection of these vehicles as I feel they do not get enough recognition. Words & photos by Mick House.

Part 2 of Network Rail Measurement Train

Rolling Stock. By Mick House.

We see a number of Network Rail Measurement Trains visit our area over the years and predominantly the photos that have been taken are of the Locomotives that bring the trains down, but what of the rolling stock that is within the train! Most of the vehicles you see are ex passenger carrying coaches or vehicles that have been used for other railway duties. I have put together a selection of these vehicles as I feel they do not get enough recognition. Words & photos by Mick House.

Network Rail Measurement Train Rolling Stock (part 1). By Mick House.

We see a number of Network Rail Measurement Trains visit our area over the years and predominantly the photos that have been taken are of the Locomotives that bring the trains down, but what of the rolling stock that is within the train! Most of the vehicles you see are ex passenger carrying coaches or vehicles that have been used for other railway duties. I have put together a selection of these vehicles as I feel they do not get enough recognition. Words & photos by Mick House.

Mobile Flash Butt Welder

By Mick House.

This article was first published in our winter 2012 Magazine.

Extra photos have been added to this article.

Another trip to Truro yard, and we have a Flash Butt Welder (take those thoughts right out of your head this is a clean magazine).

ATMW 751 All Terrain Mobile Flash Butt Welder (picture 01) developed, operated and run by Future Welding Limited (UK) is a Doosan Solar DX160W wheeled excavator machine fitted with Philmor Rail (UK) rail guidance (picture 02) and Holland K-922 welding head and Deutz rear-mounted power pack and Generator.

The DX160W wheeled excavator machine with Double cab. It has a Doosan DL06 “Common rail” 6-cylinder direct fuel injection electronic controlled diesel engine, it is water cooled, and turbo charged with air-to-air intercooler and is 128 HP at 2200 RPM with a travel speed 10 - 37 km/h (6 – 23 mph), Operating Weight is 15,300 kg (32,408 lb) without the welder and power pack.

Rail guidance is by rail wheels mounted on axles with hydraulically operated rams that engage the wheels on to the track when the machine is in position over the rails, when in position the rams are locked.

The welder (picture 03) has a working voltage: 380 to 480 volt ± 10%. Primary current: 540 amps, welding current: 30,000 amps, working pressure in hydraulic system: 207 bar (3000 psi). clamping force: 320 Tons (290 metric tons) this is the force used to grip the two rail to be welded, upset / pull force: 132 Tons (120 metric tons) this is the pull exerted on the two rails to bring them together for welding, welding / pulling stroke: 150 mm (5.9 inches) and a weight: 3100 kg (6,834lbs). The welder also has a Paton Pulse process allowing for shorter weld time, less welding material, less surface area of heat and 90% fewer defects in the finished weld giving a uniform hardness.

The rear-mounted power pack and Generator is a Deutz V6 diesel engine 322 – 670 hp at 1900 - 2100 rpm with Marathon Electric Magnaplus Generator.

The machine is able to operate in a 360 degrees radius with a reach of 5.91m (19ft 4in) from its centre on or off rail. It is also able to work under live overhead line equipment and can perform up to 12 welds per hour.

Words & Photos By Mick House.

ATMW 751 All Terrain Mobile Flash Butt Welder (picture 01) developed, operated and run by Future Welding Limited (UK) is a Doosan Solar DX160W wheeled excavator machine fitted with Philmor Rail (UK) rail guidance (picture 02) and Holland K-922 welding head and Deutz rear-mounted power pack and Generator.

The DX160W wheeled excavator machine with Double cab. It has a Doosan DL06 “Common rail” 6-cylinder direct fuel injection electronic controlled diesel engine, it is water cooled, and turbo charged with air-to-air intercooler and is 128 HP at 2200 RPM with a travel speed 10 - 37 km/h (6 – 23 mph), Operating Weight is 15,300 kg (32,408 lb) without the welder and power pack.

Rail guidance is by rail wheels mounted on axles with hydraulically operated rams that engage the wheels on to the track when the machine is in position over the rails, when in position the rams are locked.

The welder (picture 03) has a working voltage: 380 to 480 volt ± 10%. Primary current: 540 amps, welding current: 30,000 amps, working pressure in hydraulic system: 207 bar (3000 psi). clamping force: 320 Tons (290 metric tons) this is the force used to grip the two rail to be welded, upset / pull force: 132 Tons (120 metric tons) this is the pull exerted on the two rails to bring them together for welding, welding / pulling stroke: 150 mm (5.9 inches) and a weight: 3100 kg (6,834lbs). The welder also has a Paton Pulse process allowing for shorter weld time, less welding material, less surface area of heat and 90% fewer defects in the finished weld giving a uniform hardness.

The rear-mounted power pack and Generator is a Deutz V6 diesel engine 322 – 670 hp at 1900 - 2100 rpm with Marathon Electric Magnaplus Generator.

The machine is able to operate in a 360 degrees radius with a reach of 5.91m (19ft 4in) from its centre on or off rail. It is also able to work under live overhead line equipment and can perform up to 12 welds per hour.

Words & Photos By Mick House.

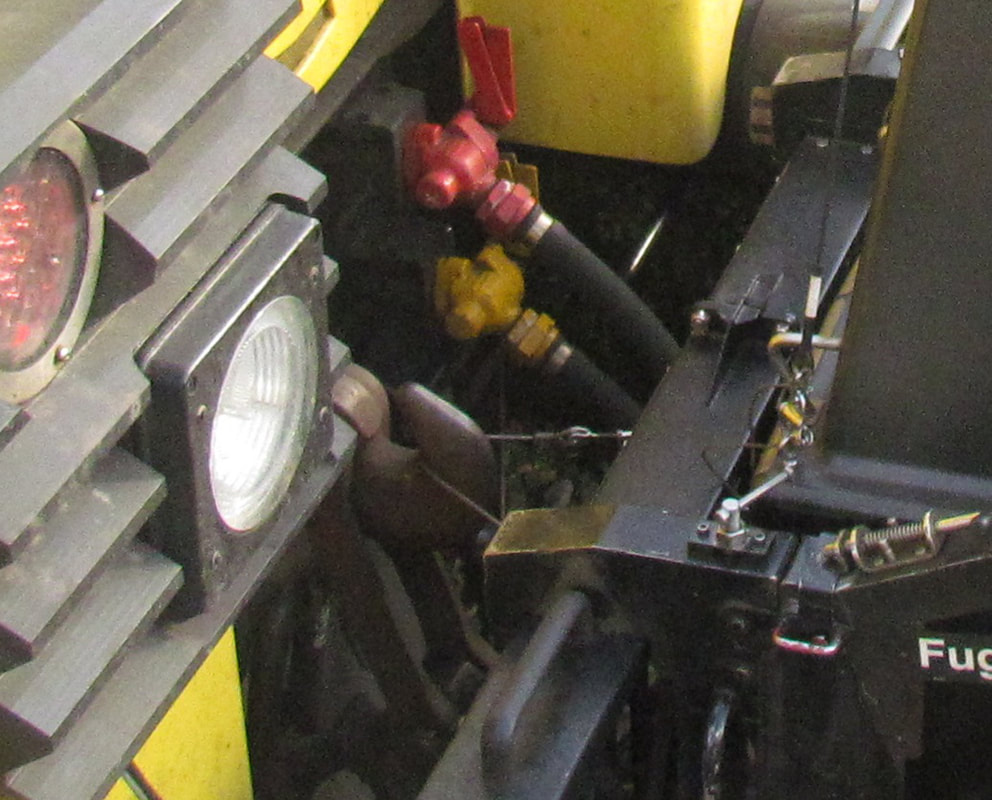

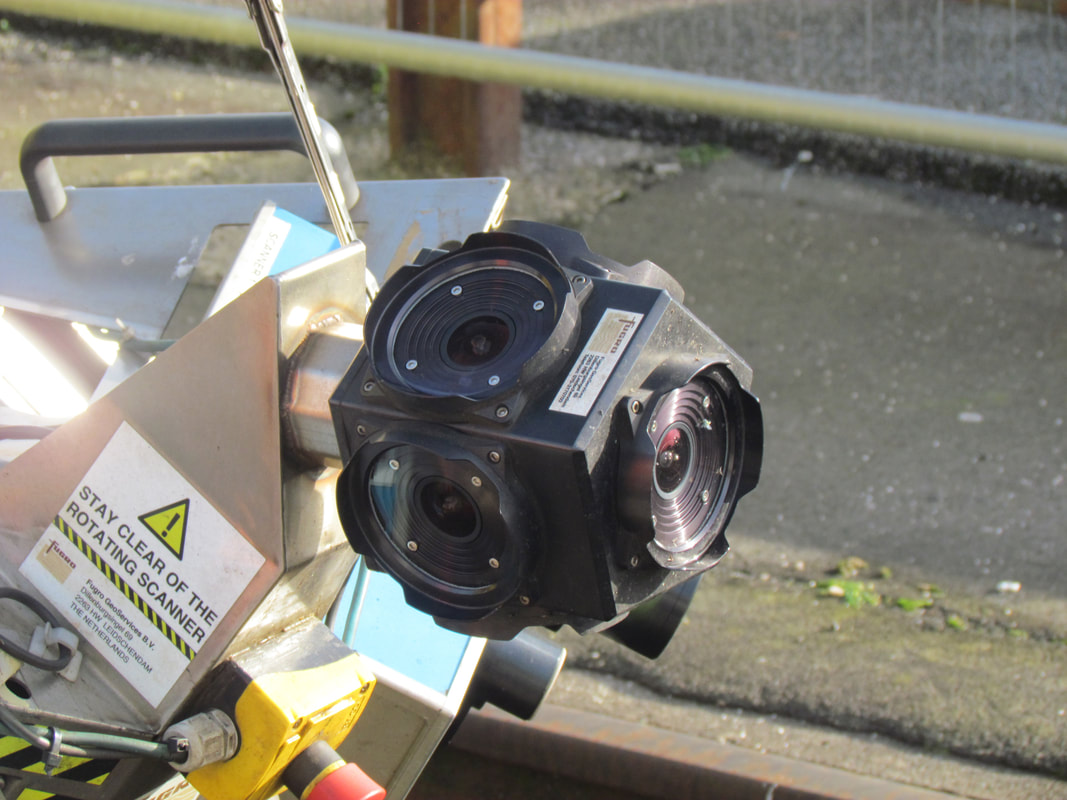

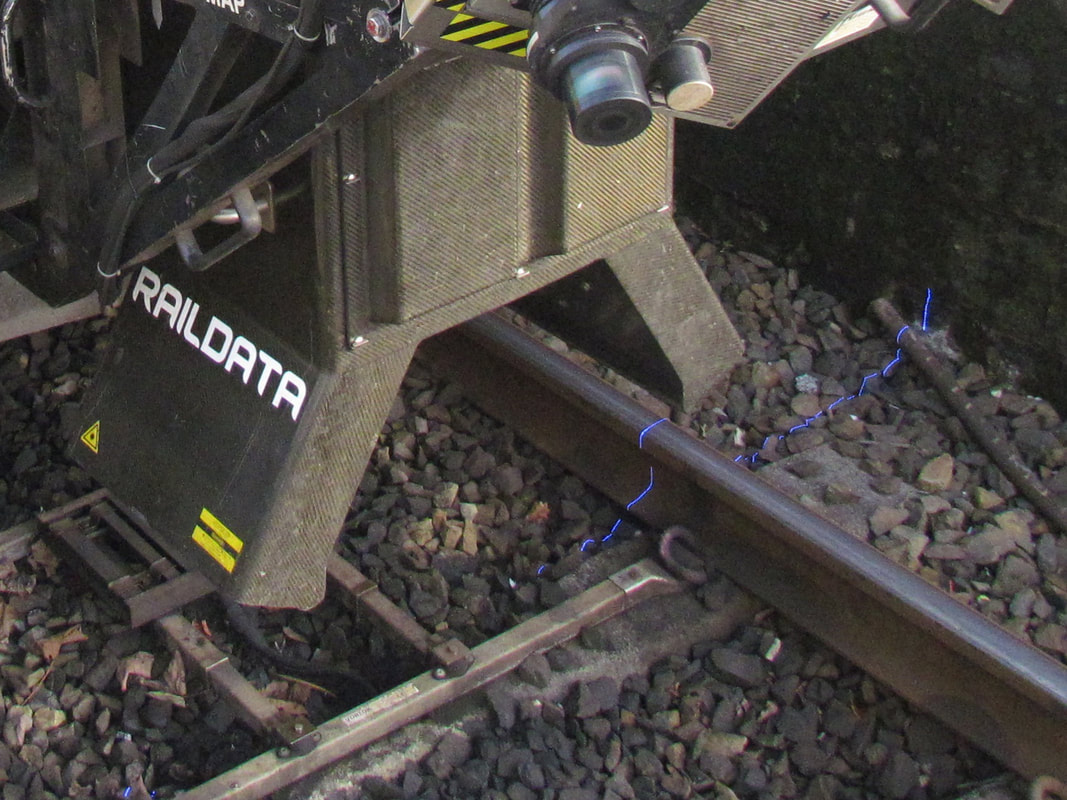

The Fugro`s, Rila and Rail-Map solutions.

Words and photos by Mick House.

Network Rail had awarded RailData a subsidiary of Fugro a contract for survey and design works to support its High Output Track Renewal Programme for 2016-17.

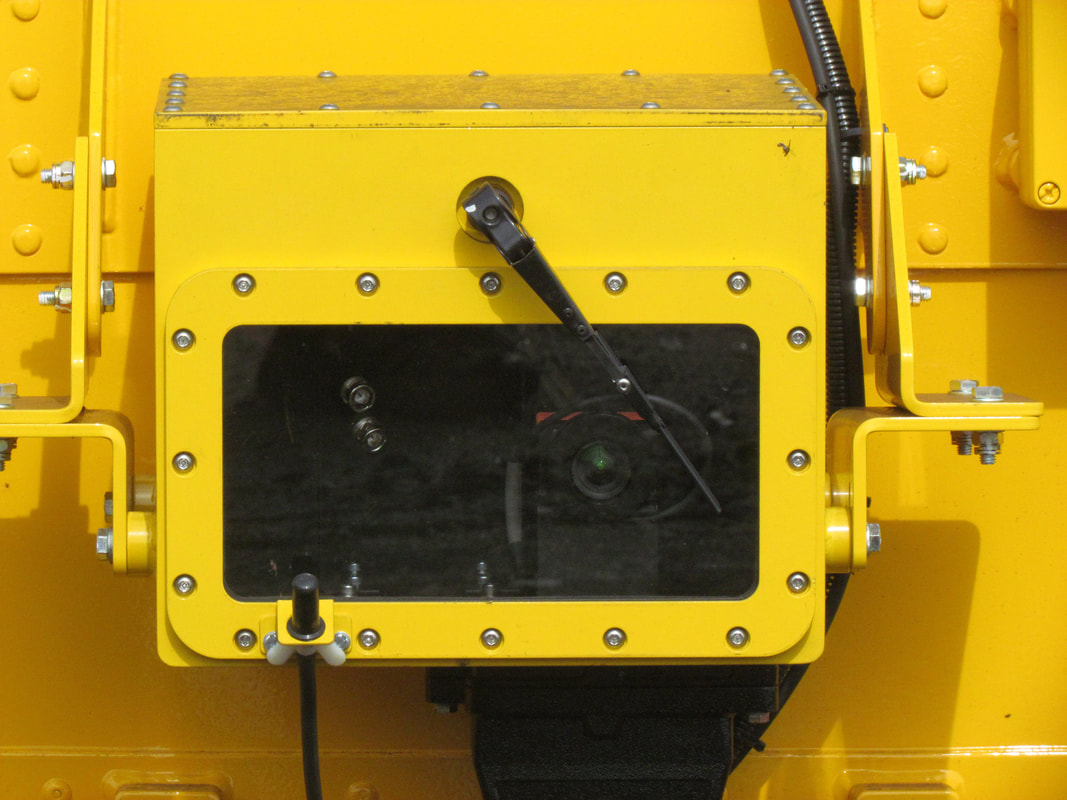

Fugro is a company based at Leidschendam in the Netherlands. They have developed and are the world’s largest integrator of geotechnical, survey, subsea and geosciences services. Among they’re various systems RailData has Rila; this is for use in railway application. RailData will apply its train-mounted Rila system to deliver highly accurate rail infrastructure information with additional ground survey services provided by UK-based Severn Partnership. This approach will enable a phased and controlled transfer from conventional survey methods to advanced train-mounted systems to deliver the information critical to track renewal schemes and will deliver significant health and safety benefits to Network Rail by greatly reducing the requirement for survey personnel to be on or near the track during the collection of survey data and also allowing trains to run safely on adjacent lines, minimising disruption to services.

This system can record and take in data at a speed of 160kph (99.4mph). The system is a portable platform that can be mounted on the front or rear of a locomotive or train its only requirements are a power supply and laptop connection. The system is mounted on the buffers of the train/loco with clamps and a safety wire to the draw/gedge hook and can be installed by two men in a matter of minuets; they also travel with the system to record and monitor it via the laptop. The system has two GPS navigation pods mounted on top, a laser array at the bottom, and a six head camera in the middle, just below that are two 3D giros.

Fugro is a company based at Leidschendam in the Netherlands. They have developed and are the world’s largest integrator of geotechnical, survey, subsea and geosciences services. Among they’re various systems RailData has Rila; this is for use in railway application. RailData will apply its train-mounted Rila system to deliver highly accurate rail infrastructure information with additional ground survey services provided by UK-based Severn Partnership. This approach will enable a phased and controlled transfer from conventional survey methods to advanced train-mounted systems to deliver the information critical to track renewal schemes and will deliver significant health and safety benefits to Network Rail by greatly reducing the requirement for survey personnel to be on or near the track during the collection of survey data and also allowing trains to run safely on adjacent lines, minimising disruption to services.

This system can record and take in data at a speed of 160kph (99.4mph). The system is a portable platform that can be mounted on the front or rear of a locomotive or train its only requirements are a power supply and laptop connection. The system is mounted on the buffers of the train/loco with clamps and a safety wire to the draw/gedge hook and can be installed by two men in a matter of minuets; they also travel with the system to record and monitor it via the laptop. The system has two GPS navigation pods mounted on top, a laser array at the bottom, and a six head camera in the middle, just below that are two 3D giros.

The Fugro’s, Rila system at the time the photos were taken, was travelling through Cornwall, mounted on a Colas class 70 810 and Class 66 850 (David Maidment OBE), I have also photographed it on Colas 66 847.

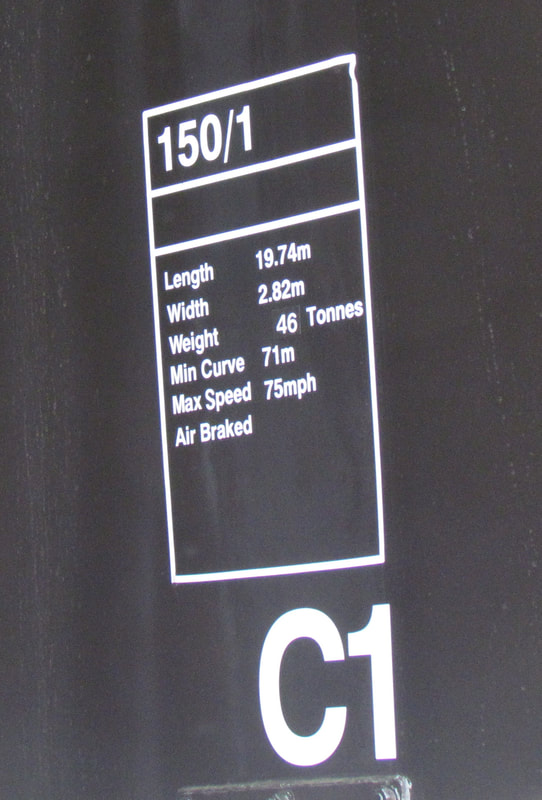

Track Recording Train 950001 in Truro Yard part 2, a detailed look at the train this may be of interest to those of you that may wish to model this two car unit.

By Mick House.

Since our last look at this train it has had a paint job and some extra decalls with new logos added to give it a new look.

The unit is fitted with two Cummins NT855-R5 diesel engines rated at 285 Horse Power and with Voith transmission.

All words, photo and inserts by Mick House with

some additional internal photos by Alan Peters.

The unit is fitted with two Cummins NT855-R5 diesel engines rated at 285 Horse Power and with Voith transmission.

All words, photo and inserts by Mick House with

some additional internal photos by Alan Peters.

Network Rail HST. By Mick House.

As one of the most travelled HSTs the Network rail measurement train is a common site around the country and we in Cornwall get our fair share if it down here. The train formation is two power cars and fire Mark 3 coaches all in the bright yellow livery. Three power cars are available 43 013/014 & 062; all have been up rated with Paxman Valenta engines. Photos were taken at Wheal Bois foot crossing to the east of Redruth, between Treleigh and Mount Ambrose and Penzance. Words and photos by Mick House.

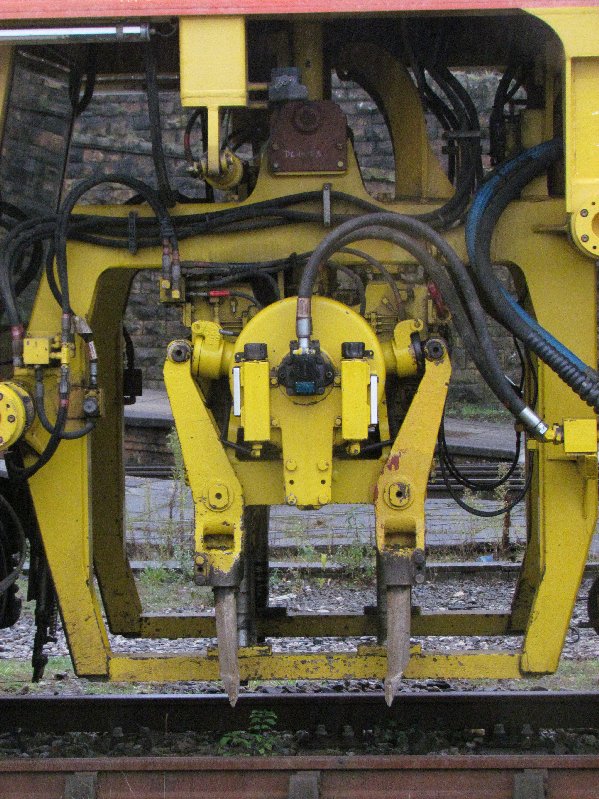

Colas Tamper DR73920 and class 153s.

By Mick House.

Colas DR73920 arrived in Truro yard today (28/03/2018) from Tavistock Junction.

C2103 Martin Elwood visits Truro.

By Mick House.

Network Rails Loram rail grinder, C2103 Martin Elwood arrived in Truro yesterday (13/01/2018) having departed Tavistock Junction at 00.17 in the morning. This is not the first time that this machine has visited Cornwall; she was around on the 21st January 2015 having visited Penzance and being stabled at St Blazey in the old goods yard behind the station. The train consists of two driving cars, one fluid car and four grinding cars. The formation is: DR29251 Driving car, DR29252 Fluid Car, DR29253 Grind Car, DR29254 Grind Car, DR29255 Grind Car, DR29256 Grind Car and DR29257 Driving car. I have put rather a lot of photos on in the form of a slide show depicting the length of the train starting on the forth photo down, they may be of use to modellers.

Photos and words By Mick House.

Photos and words By Mick House.

Colas DCR 78226 & DCR 78235 Heavy Duty Twin Jib Rail Cranes.

By Mick House and Roger Aston.

Below we have a selection of photos taken of two of the Colas Heavy Duty Twin Jib Rail Cranes.

Click on the play button in the top left-hand corner of the image to view a slideshow with a selection of shots.

Words & photos by Mick House & Roger Aston.

Many thanks Roger.

Click on the play button in the top left-hand corner of the image to view a slideshow with a selection of shots.

Words & photos by Mick House & Roger Aston.

Many thanks Roger.

Close-up shots of DRC 78235, maybe useful for modellers. Copyright Roger Aston

DCR 78226 in action. Copyright Mick House.

DR 80205 at Truro. By Mick House and Roger Aston.

Colas Rail DR77901 Ballast Regulator.

By Mick House and Roger Aston.

DR 77901 arrived in Truro at 13.09 on Friday 1st July when I photographed it.

It has been working in the Probus area.

Roger photographed it on Wednesday 6th July.

Fitters on both days were conducting routine maintenance and equipment operation after the machine had been used.

This machine is used to move ballast in to the sleepers for tamping, removing surplus ballast and tiding up the site after ballasting.

The machine has Ploughs, Brushes, Conveyors and a Storage Hopper.

Words and photos By Mick House additional photos by Roger Aston.

Many Thanks Roger.

It has been working in the Probus area.

Roger photographed it on Wednesday 6th July.

Fitters on both days were conducting routine maintenance and equipment operation after the machine had been used.

This machine is used to move ballast in to the sleepers for tamping, removing surplus ballast and tiding up the site after ballasting.

The machine has Ploughs, Brushes, Conveyors and a Storage Hopper.

Words and photos By Mick House additional photos by Roger Aston.

Many Thanks Roger.

More photos of Railvac 4 in Truro yard/station today (22-01-2016) before its 11.32 departure to Westbury.

Photos by Mick House

Photos by Mick House

Railvac 4 was delivered to Truro yard this morning (13/01/2016) and is planned to be vacuuming the station area in the night for a week.

All photos by Roger Aston.

Tamper DR 73805 from Liskeard to Penzance.

By Mick House

DR 73805 left Liskeard today at 09.59 one minute early and arrived at Penzance 11.33 three minutes early, I photographed it at Gwinear road level crossing.

By Mick House

By Mick House

Track Recording Train 950001 in Truro Yard part 1, a detailed look at the train this may be of interest to those of you that may wish to model this two car unit.

By Mick House with additional photos by Roger Aston.

In our next instalment Part 2 of the Track Recording Train 950001 in Truro Yard we will take a look at the details below sole bar and the equipment used on the train.

Multi-purpose Stone Blower, Railhead Treatment Train and Tamper.

Photos by Roger Aston & Mick House.

Network Rail`s Multi-purpose Stone Blower DR 80302 was in

Truro yard on the morning of 7th April 2015. By Roger Aston.

Many thank Roger.

Network Rail`s Railhead Treatment Train photographed at Par and Falmouth docks. By Mick House

Now Colas Rail formally Seco-Rail Tamper DR 73805.

At the beginning of this engineering section I put a photo of DR 73805 number one end in its Colas Rail livery 24th January 2015, I have dug out some more photos giving you a bit more of its history, one shot looking from the number two end taken 9th November 2012 in an unbranded state with the Seco-Rail decals removed, two shots of the business end of the machine and one shot again taken on the 24th January 2015 from number two end showing the branding it carries today of Colas Rail. By Mick House

At the beginning of this engineering section I put a photo of DR 73805 number one end in its Colas Rail livery 24th January 2015, I have dug out some more photos giving you a bit more of its history, one shot looking from the number two end taken 9th November 2012 in an unbranded state with the Seco-Rail decals removed, two shots of the business end of the machine and one shot again taken on the 24th January 2015 from number two end showing the branding it carries today of Colas Rail. By Mick House

Colas Rail Ballast Regulators in Truro.

By Roger Aston.

Colas Rail Ballast Regulator 7790 was being prepared to depart for Tavistock Junction at 09.55 on 31/08/2015 and 77327 left on 03/08/2015 at 10.40.

Photos by Roger Aston With additional photos by Mick House.

Many Thanks Roger.

Photos by Roger Aston With additional photos by Mick House.

Many Thanks Roger.

Colas Rail Tamper 75406

Colas Rail Tamper 75406 built by Matisa.

Arrived in Truro on Tuesday 7th July Photos By Mick House

Additional photos taken on Thursday 9th July By Roger Aston, Many Thanks Roger

Arrived in Truro on Tuesday 7th July Photos By Mick House

Additional photos taken on Thursday 9th July By Roger Aston, Many Thanks Roger

Harsco RGH20C rail grinder DR79263/73 in Truro yard 12/06/2015

Plant is in Truro yard for the track renewal of

Highertown Tunnel

14-05-2015

20150514 TXM Plant 6162 Truro Yard

20150514 TXM Plant 6801 Truro Yard

20150514 TXM Plant 6876 Truro Yard

Ultrasonic test train at Penzance 27/02/2015 By Mick House

The ultrasonic test train is a Class 37 97303 formerly D6878 37178 and three coaches.

The first coach: Staff/support coach No 977969 formerly BR coach 14112 / 2906 was also part of the Royal train as a Royal Household couchette (1977)

The second coach: Ultrasonic Test Coach No.999602 formerly Class 421 EMU MBSO 62483 was part of a 4 BIG unit built 1974 and converted to a Test Coach by Serco in 2008

The third coach: Driving Trailer Coach No.9701 formerly Mk.IIf BSO No.9528 built 1974, converted to DBSO for Glasgow-Edinburgh push-pull expresses in 1974 and converted again to a Driving Trailer by SERCO Derby 2008 for use with NR laboratory/testing train.

The ultrasonic test train is a Class 37 97303 formerly D6878 37178 and three coaches.

The first coach: Staff/support coach No 977969 formerly BR coach 14112 / 2906 was also part of the Royal train as a Royal Household couchette (1977)

The second coach: Ultrasonic Test Coach No.999602 formerly Class 421 EMU MBSO 62483 was part of a 4 BIG unit built 1974 and converted to a Test Coach by Serco in 2008

The third coach: Driving Trailer Coach No.9701 formerly Mk.IIf BSO No.9528 built 1974, converted to DBSO for Glasgow-Edinburgh push-pull expresses in 1974 and converted again to a Driving Trailer by SERCO Derby 2008 for use with NR laboratory/testing train.

Ultrasonic test train at Penzance

Class 37 97303

Class 37 97303 formerly D6878 37178

Staff-support coach No 977969

Ultrasonic Test Coach No.999602

Driving Trailer Coach No.9701

Driving Trailer Coach No.9701

1985

2013

A tour around Exmouth Junction PW depot.

The Pant Depot was in the old C & W depot. This originally had six roads. BR modernised three roads, taking one out which ran into the shed

Pictures by David Tozer.

The Pant Depot was in the old C & W depot. This originally had six roads. BR modernised three roads, taking one out which ran into the shed

Pictures by David Tozer.

2015